Подробности

UD-VPM - Система забора воздуха

В корпус добавлена губка предварительной фильтрации, фильтр пыли, хлопок, что снижает нагрузку на фильтрацию воздуха, продлевает срок службы фильтра воздуха; уменьшает засорение охладителя, обеспечивая эффективную работу охладителя по рассеиванию тепла.

Нанофильтрующий материал, точность фильтрации F8, эффективность фильтрации 99,99%, обеспечивает чистый воздухозаборник, снижает нагрузку на масляный сердечник, масляный фильтр, смазочное масло, продлевает срок службы; эффективно снижает разницу давления всасывания, снижает нагрузку всасывания, обеспечивает стабильную работу.

Впускной клапан большого диаметра, простой, удобный, отзывчивый, низкий перепад давления.

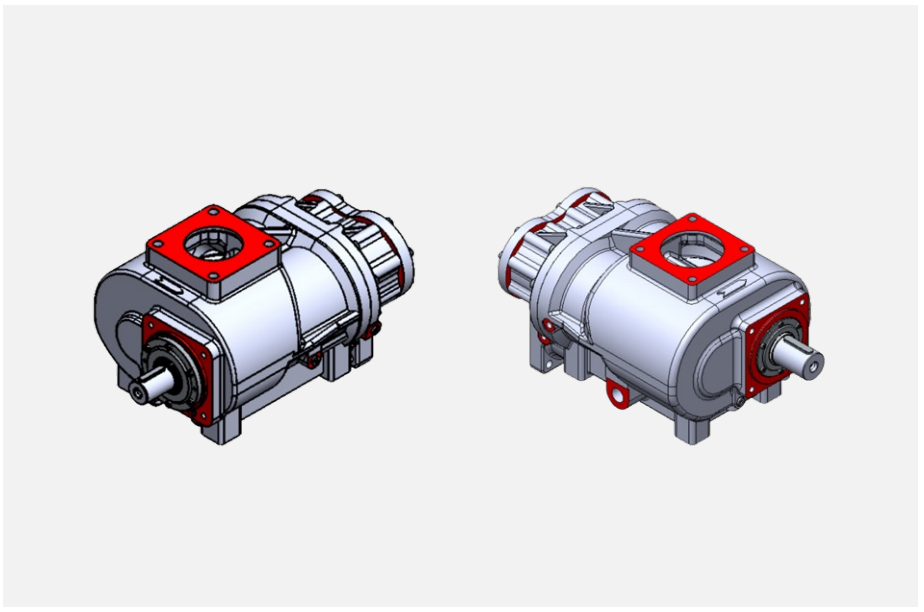

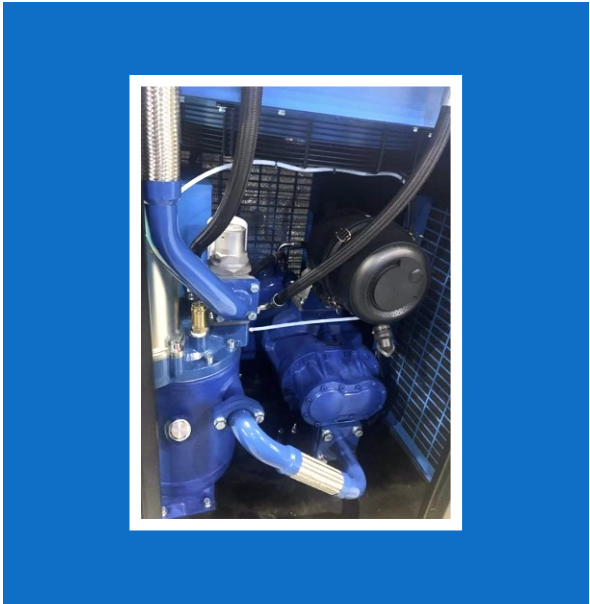

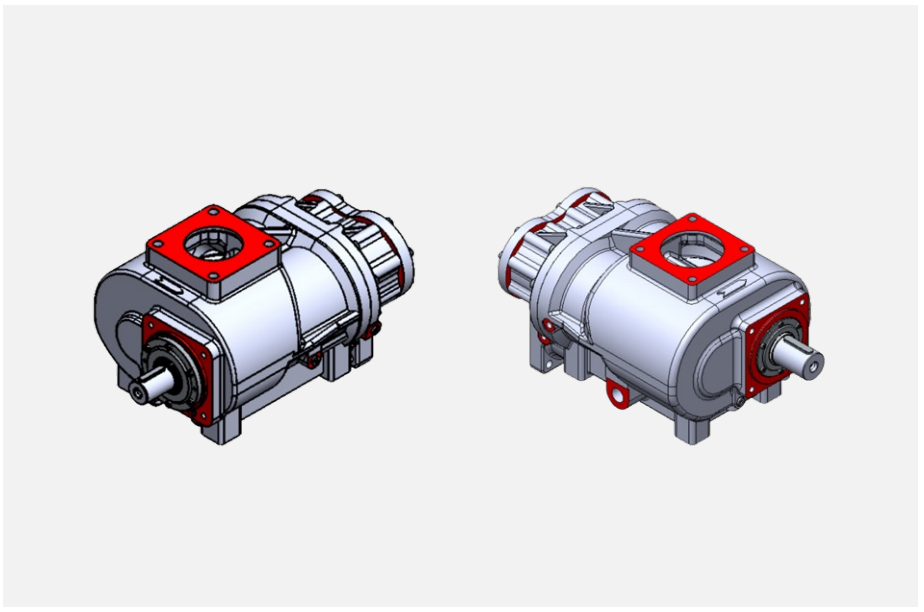

UD-VPM - Система винтового блока 1

Эффективный компрессорный блок:

Используя новое поколение линий, уплотнений, потерь мощности жидкости, достигается лучшая оптимизация и превосходная производительность.

Используя новейший метод оценки допусков формы и положения, полностью учитываются потребности винтового станка, разумное распределение зазоров, отличная производительность, высокая надежность.

Точно рассчитайте количество впрыскиваемого масла по всему объему, полностью охладите процесс сжатия, чтобы гарантировать полную смазку движущихся частей.

Специально разработанные всасывающие и выпускные отверстия для оптимальной степени сжатия.

Использование импортных подшипников SKF полностью соответствует области применения подшипников, конфигурации, смазке, сроку службы и т. д., срок службы длительный.

UD-VPM - Система винтового блока 2

Магнитная сталь масляноохлаждаемого двигателя с постоянными магнитами и преобразователем частоты изготовлена из материала на основе железа и бора, который имеет высокую собственную коэрцитивную силу, повышает способность противостоять размагничиванию и продлевает срок службы.

Имеет полностью герметичную конструкцию, оригинальную конструкцию корпуса двигателя, а также спиральную систему охлаждения. проход, равномерное охлаждение, избежание накопления температуры, вызванного слепыми зонами охлаждения, не образует локальных горячих точек, сопротивление масляному каналу меньше.

Отсутствие вентилятора двигателя, более высокая эффективность двигателя, двойной корпус двигателя, эффективная изоляция рабочего процесса шум.

Более компактная структура: высокая плотность мощности, малый объем.

Кроме того, двигатель с постоянными магнитами и преобразователем частоты является высокоэффективным двигателем IE5.

Непрерывная рабочая система (S1), ротор двигателя и вал ротора винтового блока расположены соосно, более компактно конструкция, более высокая эффективность трансмиссии, низкий уровень шума, низкая вибрация, меньшие затраты на техническое обслуживание.

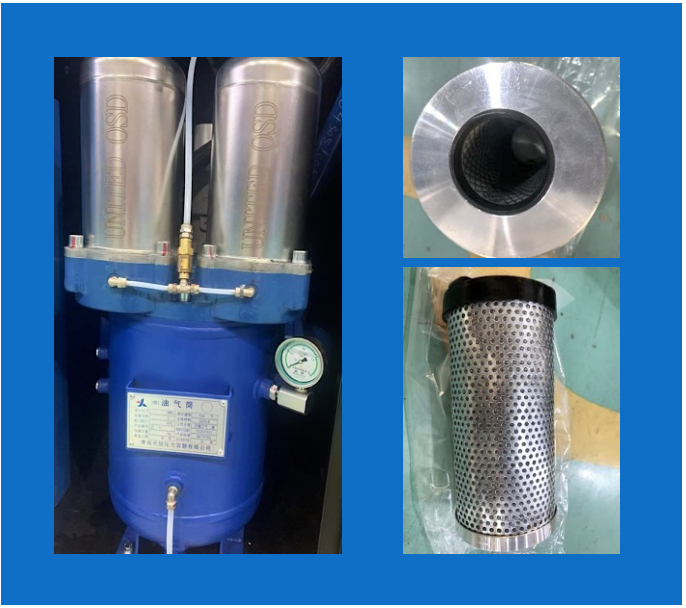

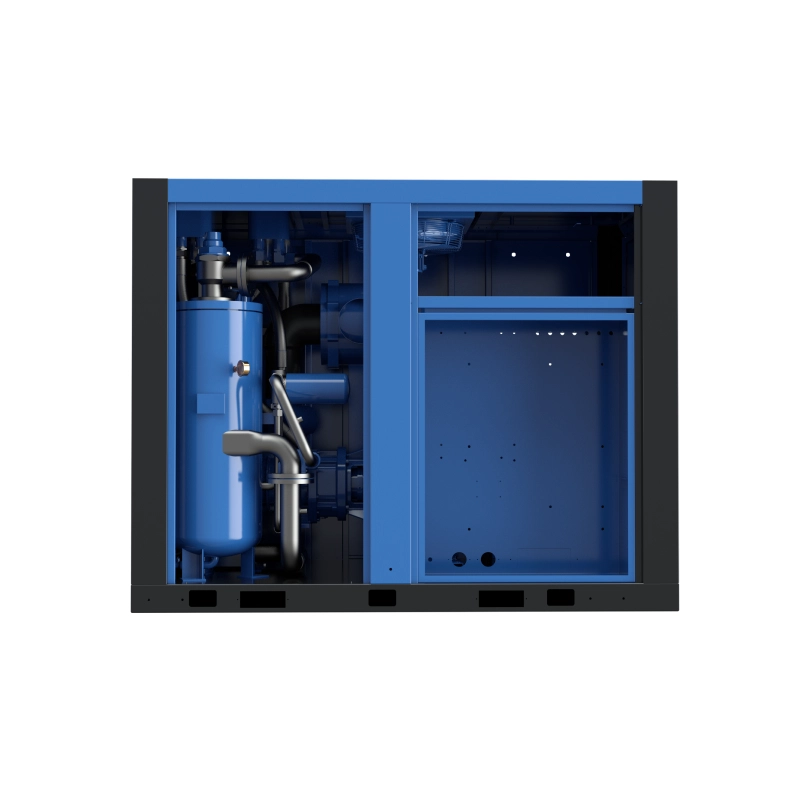

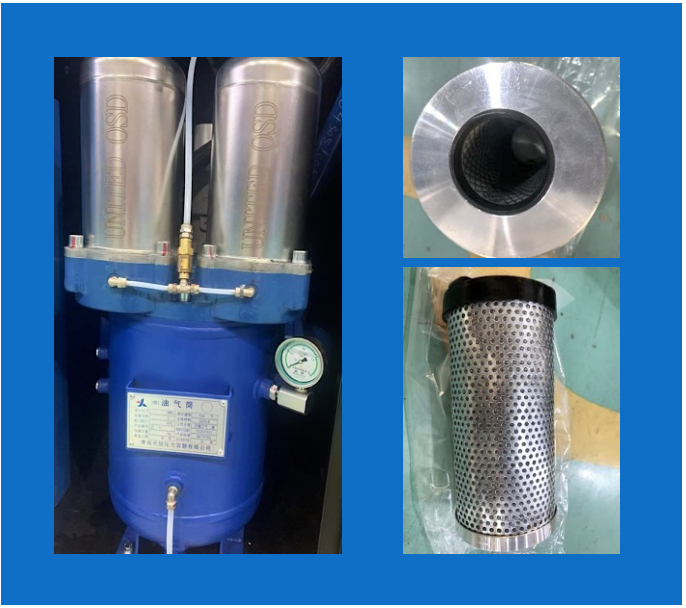

UD-VPM - Система разделения масла и воздуха

Специальная конструкция масляного и воздушного цилиндра:

(1) Используйте верхний воздухозаборник для снижения шума;

(2) Использование специально разработанного внешнего масляного сердечника, простота обслуживания;

(3) Специальная конструкция внутреннего цилиндра увеличивает начальный ход разделения масла и воздуха, предварительное разделение масла и воздуха полное, снижает нагрузку на масляный сердечник, продлевает срок его службы, уменьшает потерю давления в масляном сердечнике, таким образом, снижая потребление энергии.

Интегрированная конструкция торцевой крышки масляного и воздушного цилиндра, включающая клапан регулирования температуры и клапан минимального давления, что делает общую конструкцию более компактной.

Оригинальный импортный сердечник масляного и воздушного сепаратора, складная + плоская намоточная структура, увеличивает площадь фильтрации, хороший эффект разделения, низкий перепад давления, высокую эффективность сбора масла, хороший эффект возврата масла, и в соответствии с положениями по техническому обслуживанию, ремонту, срок службы до 4000 часов.

UD-VPM - Специальная охлаждающая жидкость

Специальная охлаждающая жидкость для воздушного компрессора UCS выбирается с учетом постоянных потребностей специальных отраслей промышленности.

Согласно требованиям компании по техническому обслуживанию, срок замены составляет до 8000 часов, что снижает затраты на техническое обслуживание.

Поскольку содержание экспортного масла низкое, он может гарантировать 4000 часов без дозаправки.

UD-VPM - Регулируемая пластина клапана

Давление открытия клапанной пластины можно регулировать произвольно, клиенты могут регулировать в соответствии с газовой ситуацией, уменьшая падение давления в системе, что обеспечивает большую экономию энергии.

Большой диаметр, снижение потерь воздушного потока и давления.

Чувствительное действие, сокращение времени установления внутреннего давления.

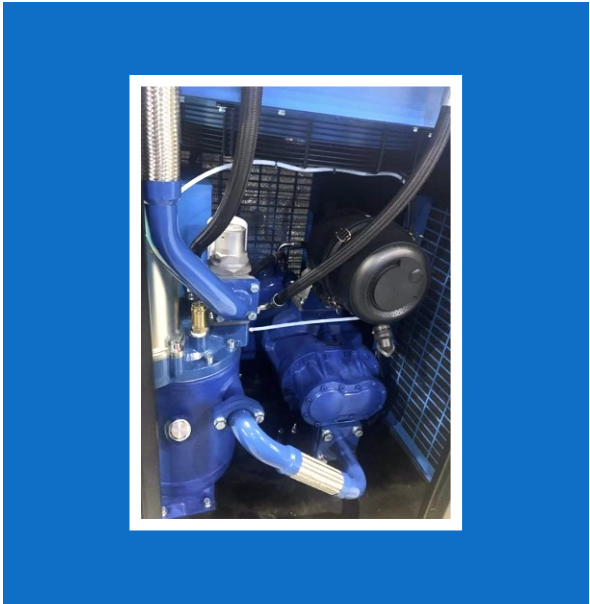

UD-VPM - Система трубопроводов

Все трубопроводные системы спроектированы с увеличенным диаметром труб и приняты большие диаметр трубы для снижения потери давления и потребления энергии.

Используется стандартный шланг с коническим уплотнением 24°, высокая надежность уплотнения, высокая взаимозаменяемость, удобная разборка и сборка.

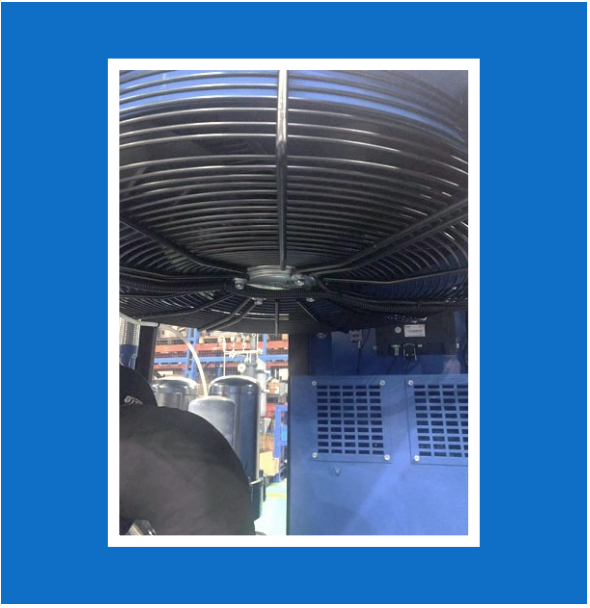

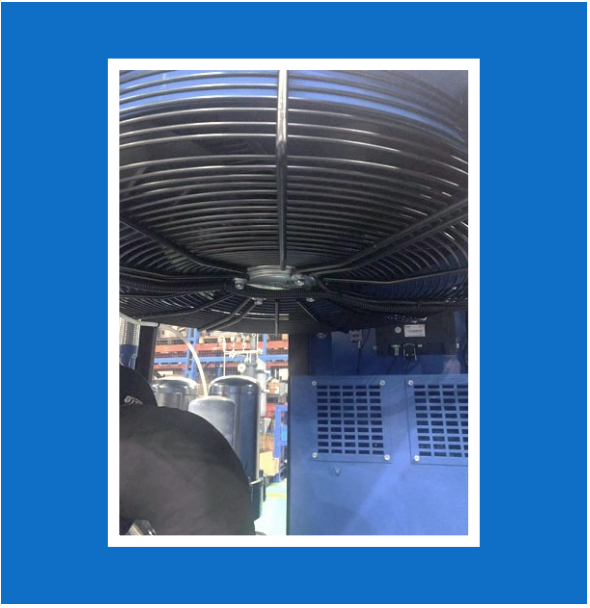

UD-VPM - Система охлаждения

Клапан регулирования температуры, стабильная температура выхлопных газов, подходит для различных сложных условий.

В охладителе используется пластинчато-ребристый теплообменник с большой площадью теплообмена, быстрым теплообменом и высокой эффективностью охлаждения.

Главной особенностью является достаточный расчетный запас, обеспечивающий надежную работу всей машины в условиях высоких температур летом.

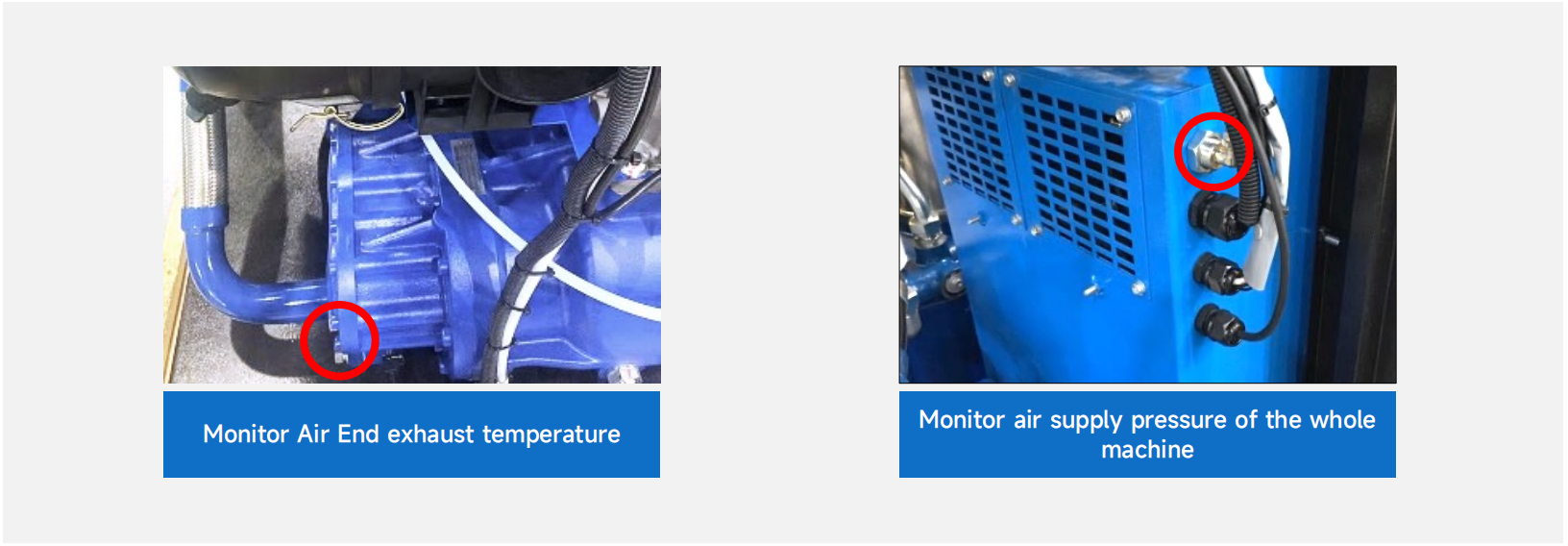

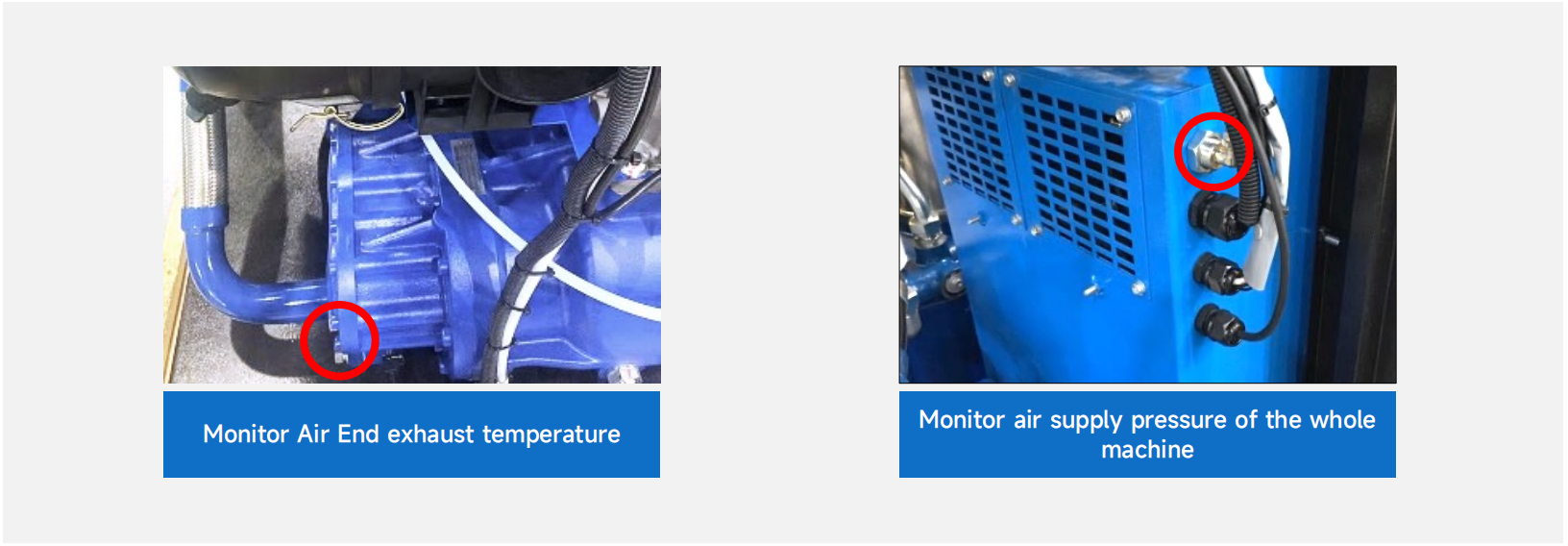

UD-VPM - Система мониторинга

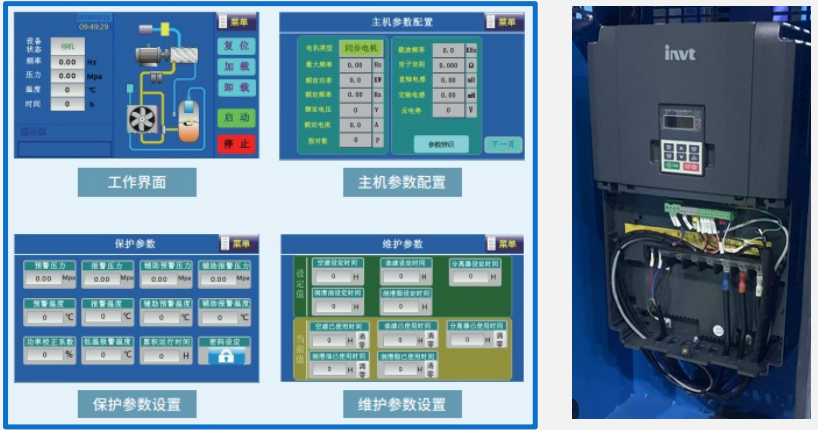

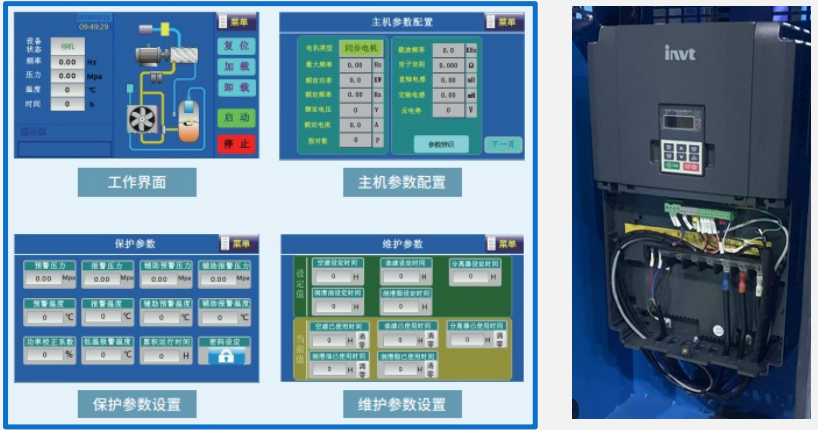

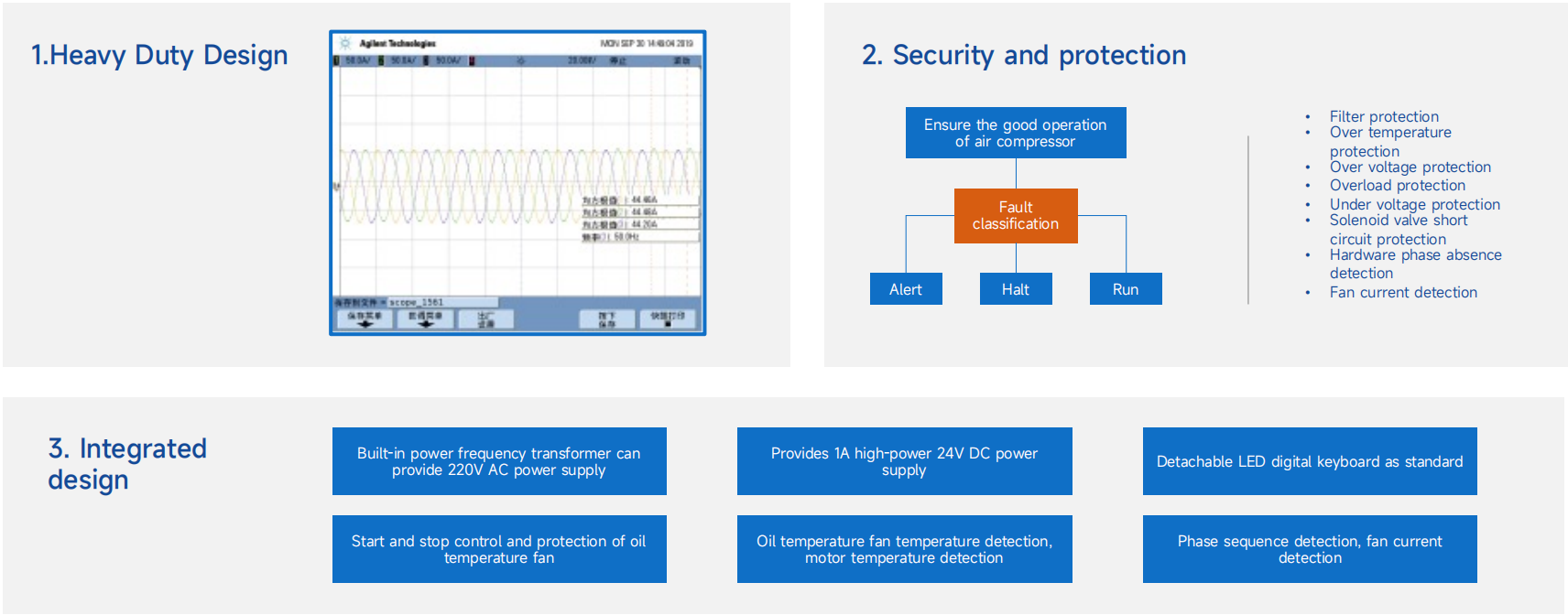

УД-ВПМ - Система управления 1

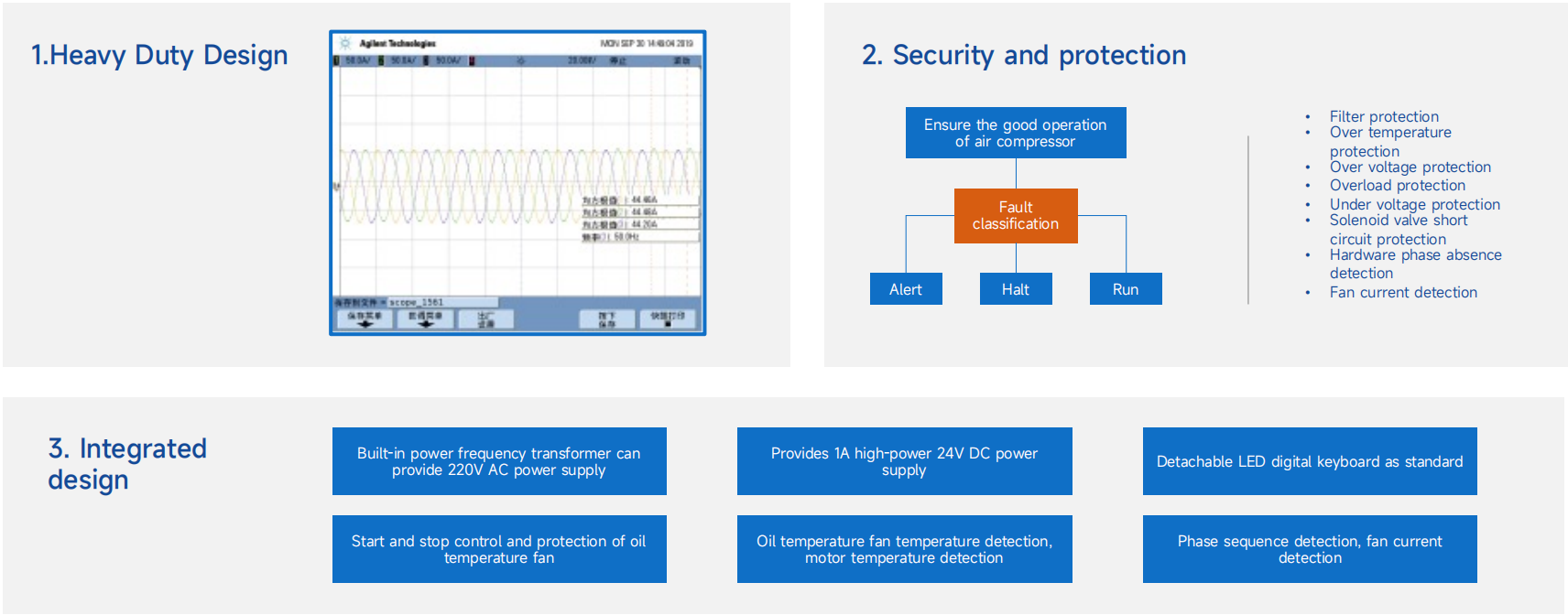

Система управления использует интегрированную машину с инвертором INVT.

Высокая адаптивность к окружающей среде - независимая конструкция воздуховода может эффективно улучшить защитный эффект преобразователя частоты, адаптироваться ко всем видам сложных и суровых полевых условий, повысить надежность изделия, продлить срок службы.

Высокая степень интеграции, меньший объем.

Специальный интерфейс «человек-машина» для воздушного компрессора.

УД-ВПМ - Система управления 2

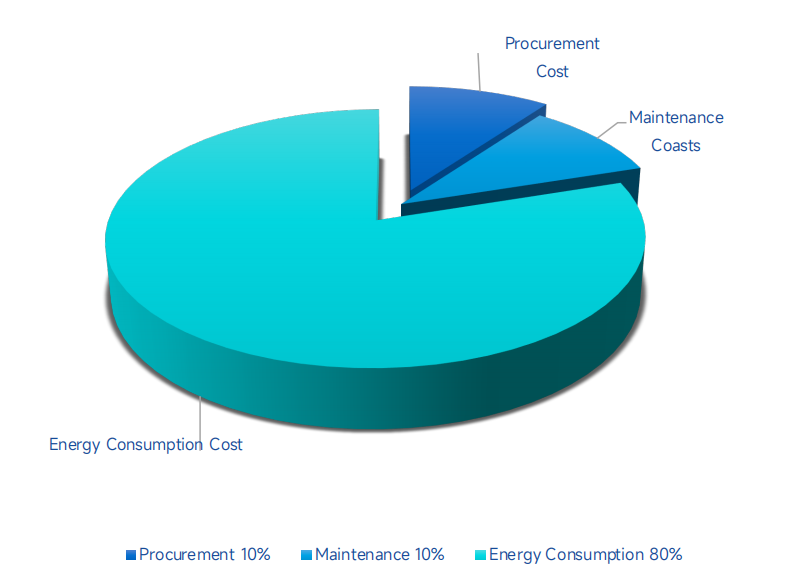

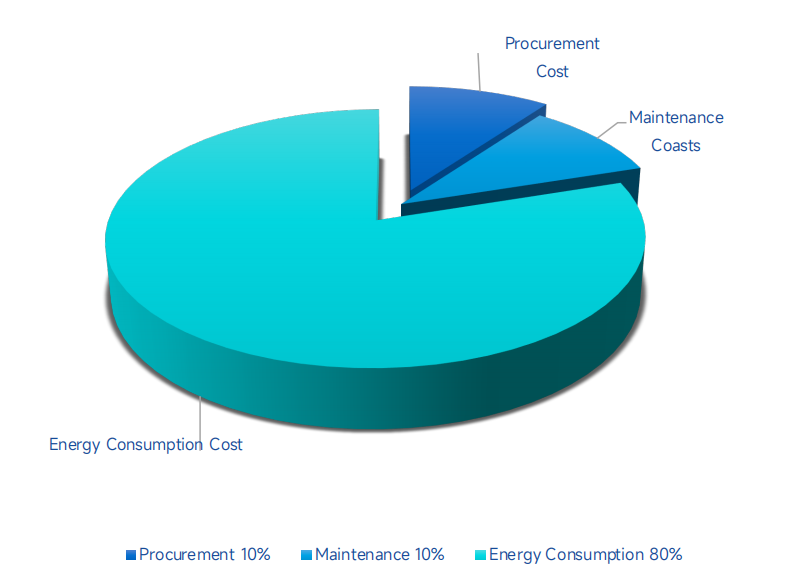

Состав стоимости воздушного компрессора

Стоимость воздушного компрессора состоит из стоимости закупки, стоимости обслуживания и энергии. Стоимость потребления. Согласно теории оценки полного жизненного цикла, стоимость закупки только составляет менее 10%, а эксплуатационные расходы составляют более 90%.

Поэтому расходы на электроэнергию и техническое обслуживание особенно важны для контроля затрат клиентов.

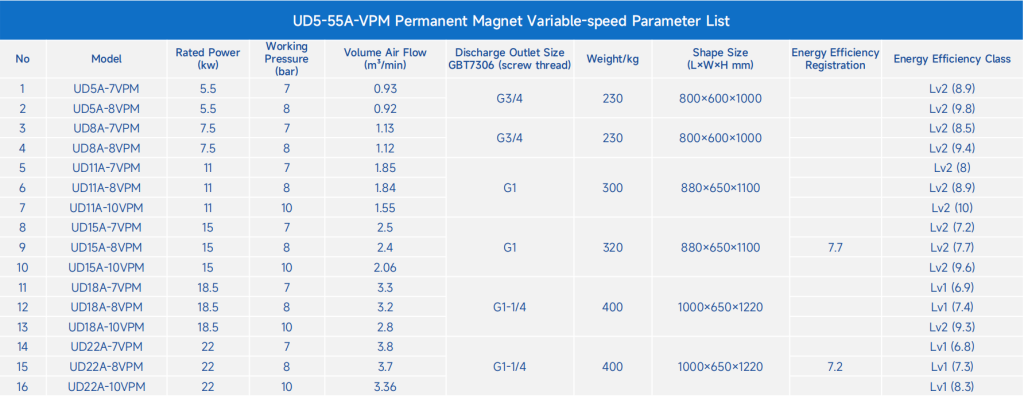

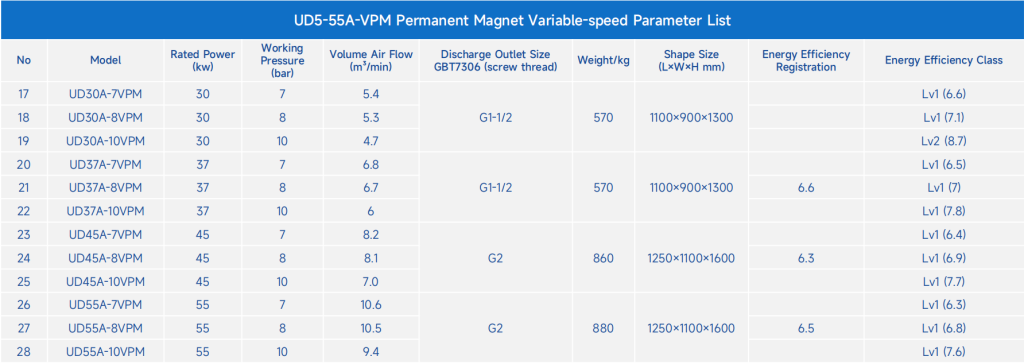

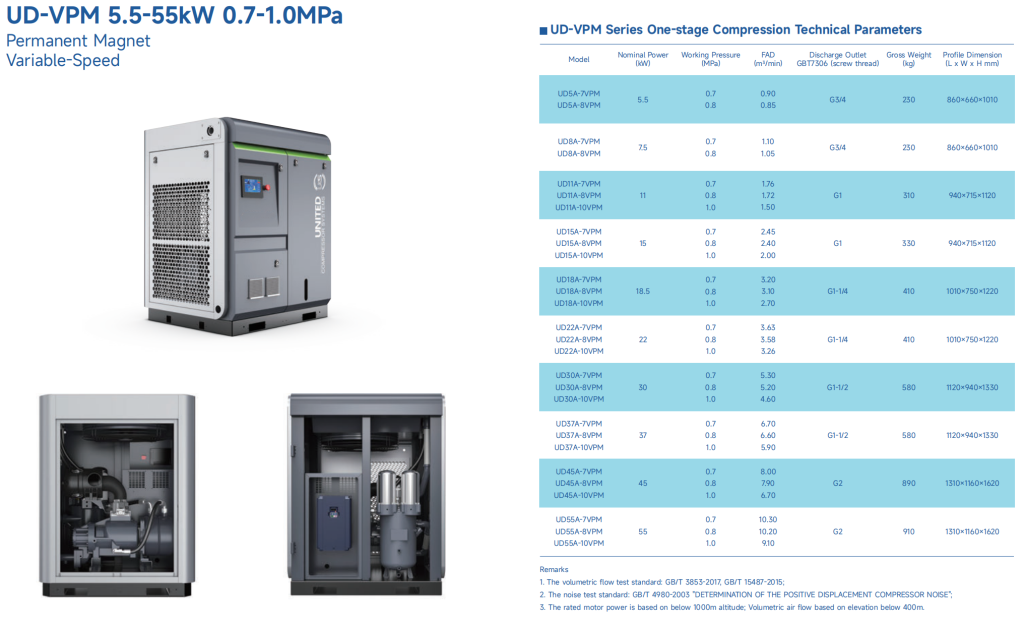

Технические характеристики продукта

Технические характеристики продукта