Product Specifications

Technical features:

1.The raw material air is taken from nature, and nitrogen can be produced only by providing compressed air and power supply. The energy consumption of the equipment is low, and the operating cost is low.

2.The purity of nitrogen is easy to adjust, the purity of nitrogen is only affected by the amount of nitrogen exhaust, and the purity of ordinary nitrogen production can be adjusted arbitrarily between 95% and 99.999%; The high-purity nitrogen generator can be adjusted between 99% and 99.999%.

3.The equipment has a high degree of automation, fast gas production, and can be unattended. Start and shut down with just one button to press a button, and nitrogen can be generated within 10-15 minutes of turning on the machine.

4.The process flow of the equipment is simple, the structure of the equipment is compact, the area is small, and the equipment is adaptable.

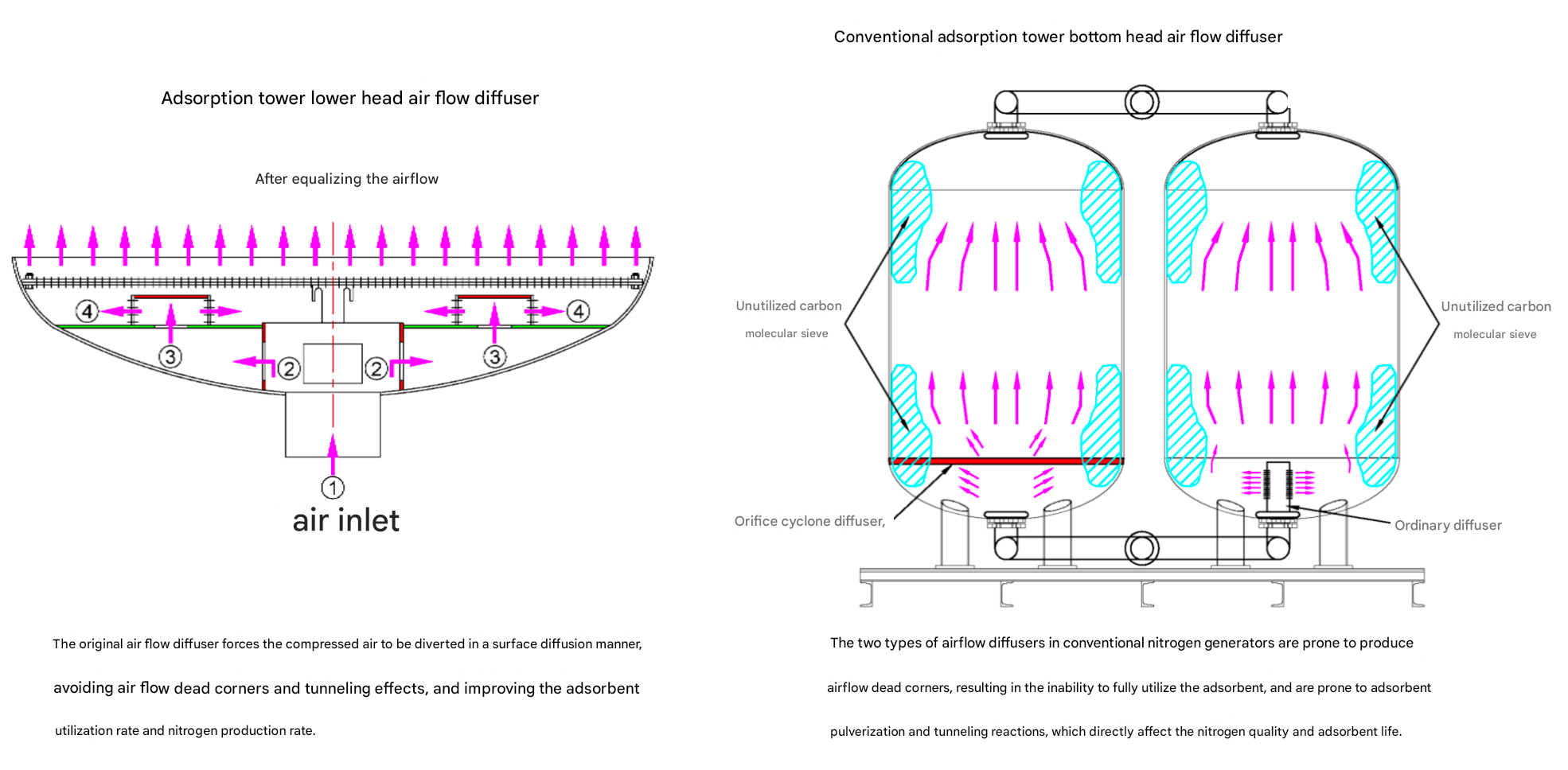

5.The blizzard method is used to fill the molecular sieve to avoid the pulverization of the molecular sieve caused by the impact of high-pressure air flow, and to ensure that the molecular sieve can be used for a long time.

6.The digital flowmeter is a secondary instrument for industrial process monitoring with pressure compensation and high precision, and has the functions of instantaneous flow and cumulative calculation.

7.On-line detection of imported analyzer, high precision and maintenance-free.

Scope of industry application

1. SMT industry application

Nitrogen-filled reflow soldering and wave soldering, nitrogen can effectively inhibit the oxidation of solder, improve soldering wettability, speed up wetting, reduce the generation of solder balls, avoid bridging, reduce soldering defects, named SMT electronics manufacturers have matched hundreds of cost-effective pressure swing adsorption nitrogen generators, and have a huge customer base in the SMT industry, with a market share of more than 90% in the SMT industry.

2. Application in semiconductor silicon industry

Atmosphere protection, cleaning, chemical recovery in semiconductor and integrated circuit manufacturing processes, etc.

3. Application in semiconductor packaging industry

Encapsulated, sintered, annealed, reduced, stored with nitrogen. Hongbo pressure swing adsorption nitrogen generator assists major manufacturers in the industry to win the first opportunity in the competition and achieve effective value enhancement.

4. Electronic components industry application

Selectively soldered, purged and encapsulated with nitrogen. Scientific nitrogen inert protection has proven to be an essential part of the successful production of high-quality electronic components.

5. Industry application in chemical and new material industries

Nitrogen is used to create an oxygen-free atmosphere in the chemical process, improve the safety of the production process, fluid transport power source, etc. Petroleum: It can be used for nitrogen purging of pipelines and vessels in the system, nitrogen filling, displacement, leak detection of storage tanks, flammable gas protection, and diesel hydrogenation and catalytic reforming.

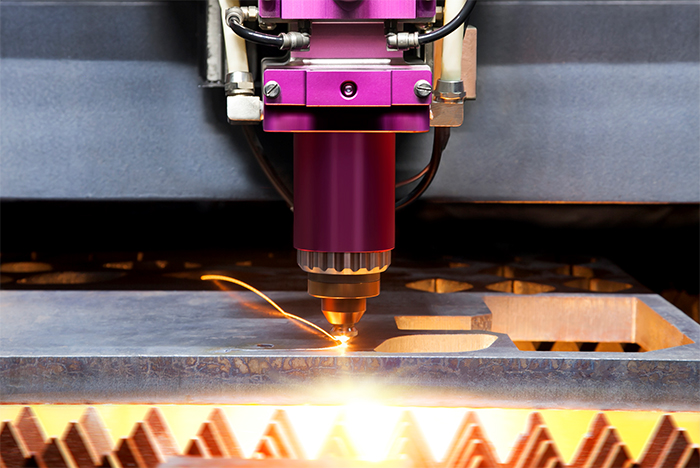

6. Powder metallurgy, metal processing industry

Heat treatment industry applications Annealing and carbonization of steel, iron, copper and aluminum products, high-temperature furnace protection, low-temperature assembly and plasma cutting of metal parts, etc.

7. Industry application in food and pharmaceutical industry

It is mainly used in food packaging, food preservation, food storage, food drying and sterilization, pharmaceutical packaging, pharmaceutical displacement gas, pharmaceutical conveying atmosphere, etc.

8. Other fields of use

In addition to being used in the above industries, nitrogen generators are also widely used in many fields such as coal mines, injection molding, brazing, tire nitrogen filling rubber, rubber vulcanization, etc. With the progress of science and technology and the development of society, the use of nitrogen equipment is becoming more and more extensive, and on-site gas production (nitrogen generator) has gradually replaced traditional nitrogen supply methods such as liquid nitrogen evaporation and bottled nitrogen with its advantages of low investment, low cost and convenient use.

Product Specifications

Product Specifications