Quelles sont les fonctions du réservoir de gaz du compresseur d'air ?

Release time: 2025-06-19

Although you know the function of the air compressor air tank, it is not comprehensive!

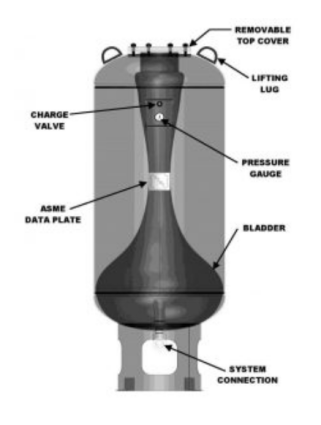

1. Store air to meet the sudden increase in gas consumption of gas-using equipment;

2. Store air and eliminate the pulsation of air flow in the pipeline;

3. Preliminary cooling of the air to allow some liquid water to precipitate. Therefore, the gas tank should be drained regularly;

4. It can ensure the automatic shutdown of the air compressor. When the gas tank is full of gas under the set pressure, the air compressor will automatically shut down, so as not to waste electricity by letting the air compressor run all the time .

Theoretically, a larger gas tank is preferable as it can decrease the frequency of air compressor startups. Star-delta starting is a method of power frequency initiation, where the motor’s starting current is approximately seven times the rated current. Frequent startups can severely damage the air compressor’s electrical components, shortening their lifespan, and can also have a significant impact on the power grid, potentially disrupting the normal operation of other electrical devices.

The variable frequency air compressor is a soft starter, and the starting current is about twice the rated current, so the impact is not very large.

Q: Is it possible to not have an air storage tank for a screw air compressor?

Enthusiastic netizen 1: The air tank at the outlet of the air compressor can not only stabilize the outlet pressure and buffer the air, but also has an important function that most users will not notice, that is, to prevent the compressed air pipeline from returning liquid for some reason during the air compressor shutdown and backflowing into the air compressor, causing damage. If the air tank is removed, the inverted U-bend design should be used in the pipeline design to achieve the same effect. I don’t know if what I said is correct, please advise.

Enthusiastic netizen 2: The function of the air storage tank is to maintain the network pressure of the compressed air system without large fluctuations. Since the air consumption at the end of the compressed air system is generally not stable at all times, the air storage tank is used to balance the stability of the system pressure and reduce the frequent loading and unloading of the air compressor. Another function is to cool the dried compressed air again to reduce the moisture content in the compressed air.

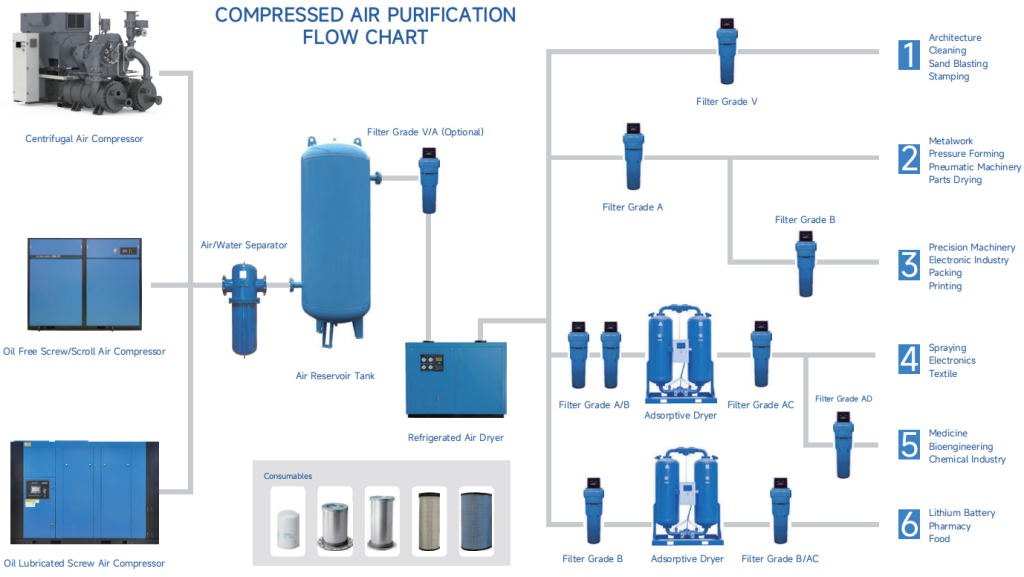

For some compressed air systems, such as those with large air compressor displacement (such as centrifugal air compressors), large system pipe network volume (large and long pipe diameters), and relatively stable air consumption, it is not necessary to equip them with air storage tanks. However, general compressed air systems need to be equipped with air storage tanks .

Enthusiastic netizen 3: There is no place to store compressed air inside the air compressor. Once the compressed air is produced, it must be used up. This working method is not ideal. With an air storage tank, the compressed air can be pumped into the air storage stall to a certain air pressure, and then used until the air pressure drops to a certain level, and then the compressor is started. This is more ideal in terms of energy utilization and compressed air quality. So it is not possible without an air storage tank.

Enthusiastic netizen 4: For equipment that requires a small amount of compressed air and is not used frequently, the air compressor does not need to store air. However, considering the stability of the air compressor performance, the constant pressure and quality of the compressed air, it is best to equip it with an air storage tank.

1. Air compressor action

Since the air compressor has a relatively large range of motion, if the pressure vessel is frequently opened and stopped during operation, this will increase the wear of the valve and make the oil and gas circuits unstable, which will cause the instability of the machine. However, if an air storage tank is installed, this situation will be relatively reduced.

2. Energy saving effect

The air compressor is frequently started and stopped, so the motor current consumption is very large. Therefore, the air compressor is in an unloaded state. If this state stays for a long time, a lot of flow will be wasted. However, if the air system is equipped with an air tank, the air compressor will stop stably, which can ensure very stable operation and reduce unnecessary idling energy waste.

3. Provide a stable gas source

Why should an air compressor be bound to an air tank? If there is an air tank in the air compressor system, there will be a buffer for the air output by the air compressor, and the air source can be better maintained at a set value, and the air system can obtain a constant pressure, which is very necessary for the use of modern factories.

4. Good air quality

The compressed air from the air compressor is first sent to the air storage. The air in it will stay for a certain period of time, which can precipitate foreign matter such as impurities and moisture in the air. The temperature of the compressed air is also reduced, so that even without a freeze dryer, relatively high-quality air can be delivered. In fact, the role of storage is like a reservoir. The air compressor is an air source, and the air storage is a pool. The air storage tank can set the air pressure within a certain pressure range according to the settings, buffer the fluctuation of air pressure, and reduce the number of times the air compressor is started. In addition, the air storage can also sink foreign matter such as impurities and moisture in the air.