Principe et fonctionnement du sécheur frigorifique à air comprimé

Release time: 2025-07-02

The moisture in compressed air often has an adverse effect on equipment and product quality. In order to solve this problem, the compressed air refrigeration dryer came into being. This article will introduce the principle and working process of the compressed air refrigeration dryer in detail.

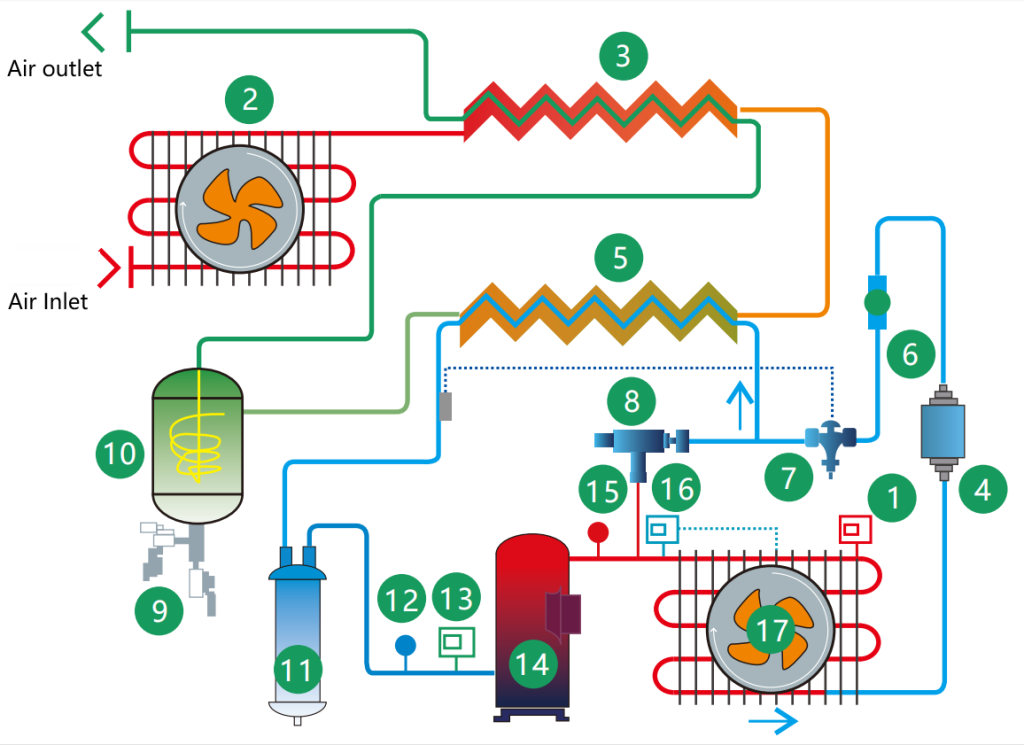

1.High voltage protection switch; 2.Air cooled pre-cooler; 3.Air heat exchanger; 4.device for drying and filtering; 5.Refrigerant evaporator; 6.Window; 7.Thermal Expansion Valve; 8.Hot gas bypass valve; 9.Hydathode; 10.Steam separator; 11.Refrigerant gas-liquid separator; 12.Refrigerant pressure gauge; 13.Low pressure protection switch; 14.Refrigerant compressor; 15.Refrigerant pressure gauge; 16.Anti-freeze switch; 17.Condenser

1.Principle of Compressed Air Refrigeration Dryer

Compressed air refrigeration dryer mainly uses refrigeration technology to cool the compressed air to below the dew point temperature, so that the water vapor in it condenses into water droplets and separates them, thereby achieving the purpose of drying the compressed air. Its working principle mainly includes the following aspects:

- Refrigeration System :

The refrigerated dryer is equipped with a refrigeration system, which is usually composed of a compressor, a condenser, an evaporator and other components. The compressor compresses the refrigerant into a high-temperature and high-pressure gas, which is then converted into a low-temperature and high-pressure liquid after being dissipated by the condenser, and then enters the evaporator after being depressurized by the expansion valve. In the evaporator, the refrigerant absorbs the heat of the compressed air, lowering its temperature.

- Air Cooling :

After the compressed air enters the refrigerated dryer, it first passes through the air filter to remove impurities and oil, and then enters the evaporator. In the evaporator, the compressed air exchanges heat with the low-temperature refrigerant, and the temperature drops rapidly.

- Water Vapor Condensation :

When the compressed air temperature drops below the dew point temperature, the water vapor in it condenses into water droplets. These water droplets adhere to the heat exchange surface of the evaporator and flow into the water separator under the action of gravity.

- Water Separation and Discharge :

The water separator separates the condensed water droplets from the compressed air and discharges the water out of the machine through the automatic drainage device. The compressed air after drying is discharged from the dryer outlet for subsequent use.

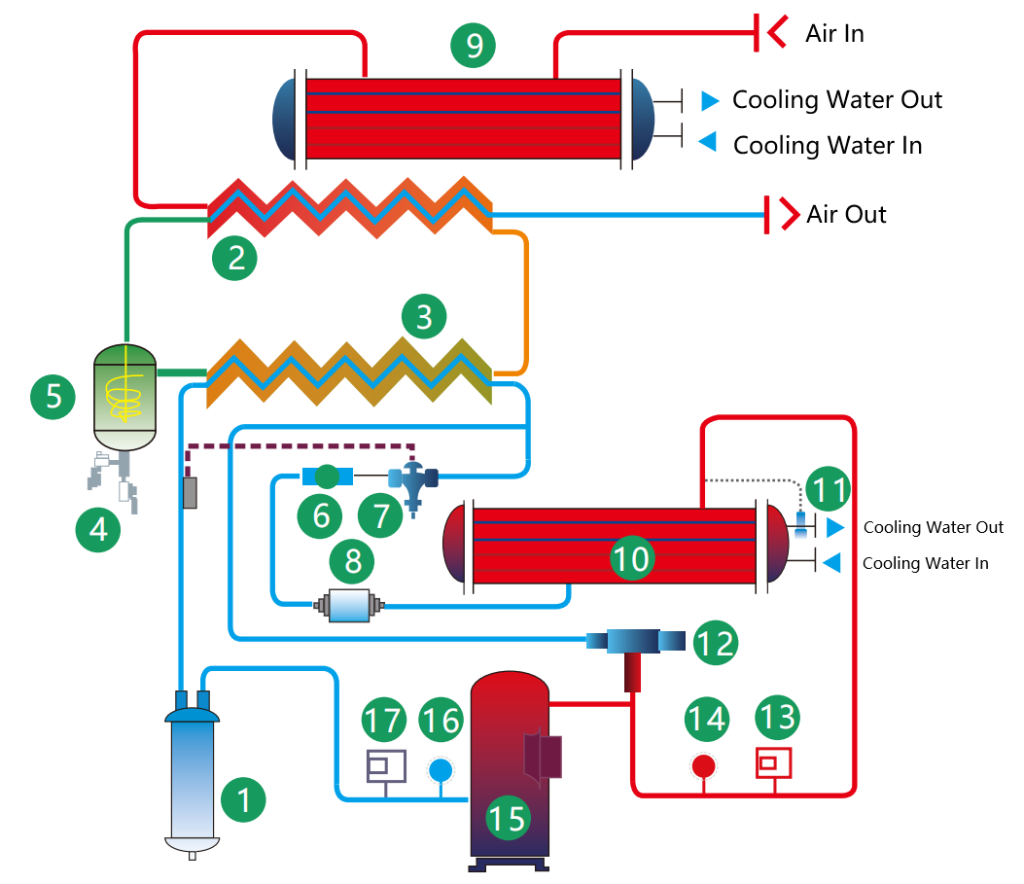

1.Refrigerant gas-liquid separator; 2.Heat exchanger; 3.Evaporator; 4.Drain; 5.Steam separator; 6.Windows; 7.Thermal Expansion Valve; 8.Filter drier; 9.Water-cooled precooler; 10.Water-cooled condenser; 11.Water flow regulating valve; 12.Hot gas bypass valve; 13.High voltage protection switch; 14.Refrigerant high pressure gauge; 15.Refrigerant compressor; 16.Refrigerant low pressure gauge; 17.Low pressure protection switch.

2.Compressed air refrigeration dryer working process

The working process of compressed air refrigeration dryer can be divided into the following steps:

- Air Entry :

Compressed air first enters the refrigerated dryer through a pipeline, and passes through an air filter to remove impurities and oil to ensure that the air entering the dryer is clean.

- Pre-Cooling:

The filtered compressed air enters the pre-cooler and exchanges heat with the already cooled air to initially reduce the temperature. This step helps improve drying efficiency and reduce the load on the refrigeration system.

- Refrigeneration Cooling :

The pre-cooled compressed air enters the evaporator and exchanges heat with the refrigerant. The refrigerant absorbs the heat of the compressed air, further reducing its temperature to below the dew point temperature.

- Water Vapor Condensation :

In the evaporator, the water vapor in the compressed air with reduced temperature condenses into water droplets and adheres to the heat exchange surface of the evaporator.

- Water Separation and Discharge :

The condensed water droplets are separated from the compressed air by the water separator and discharged out of the machine through the automatic drainage device. The water separator usually uses centrifugal force or gravity principle to separate the water droplets from the compressed air.

- Reheating :

After water separation, the dry compressed air enters the reheater to exchange heat with the untreated compressed air to increase its temperature. This step can prevent the dry air from absorbing moisture again during transportation.

- Air Output :

The dry compressed air after reheating is discharged from the dryer outlet for use by subsequent equipment. At this time, the compressed air has reached a lower dew point temperature, meeting the needs of most industrial applications.

The compressed air refrigeration dryer uses refrigeration technology to cool the compressed air to below the dew point temperature, so that the water vapor in it condenses into water droplets and separates them, thereby achieving the purpose of drying the compressed air. Its workflow includes steps such as air intake, pre-cooling, refrigeration cooling, water vapor condensation, water separation and discharge, reheating and air output. Through this series of processing processes, the refrigeration dryer can effectively remove moisture from the compressed air, ensure the quality of the compressed air, and meet the needs of various industrial applications.