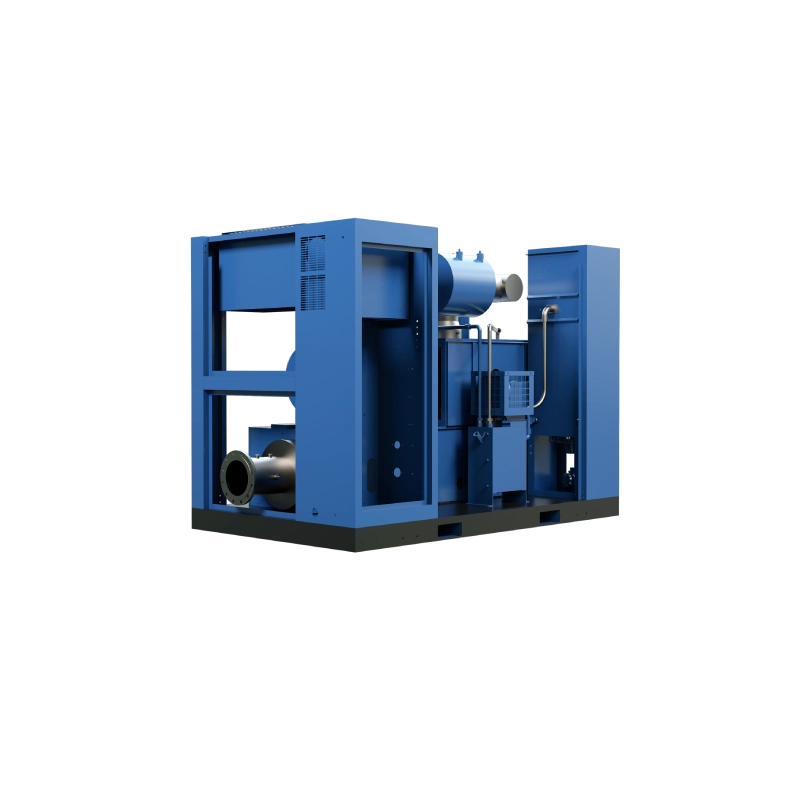

Oil-free Screw Air Blower is a high-performance product designed specifically for applications that require clean and oil-free compressed air. It is widely used in industries such as electronics, pharmaceuticals, food and beverage, and wastewater treatment.

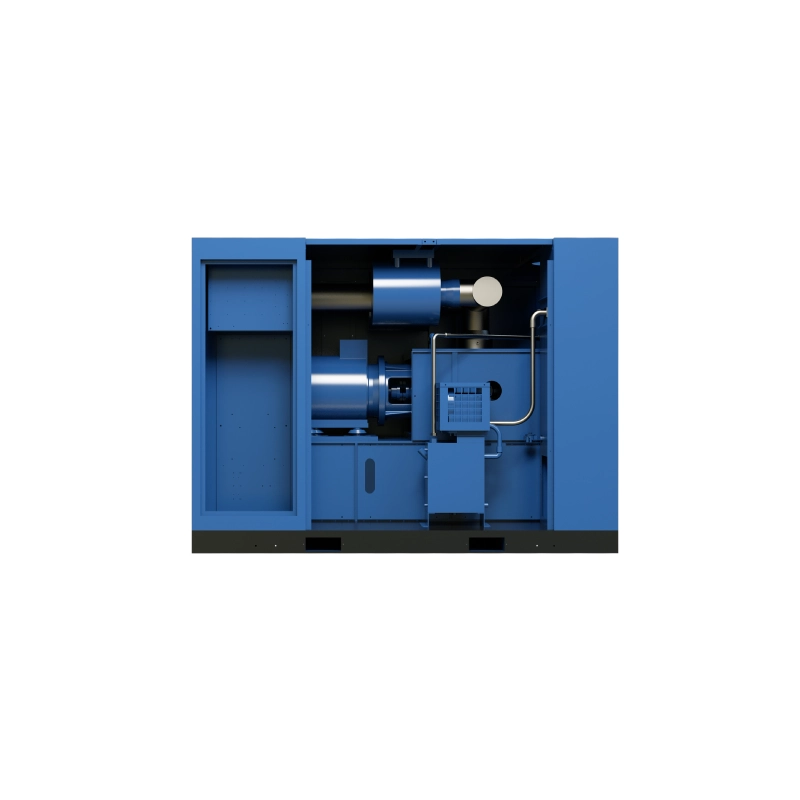

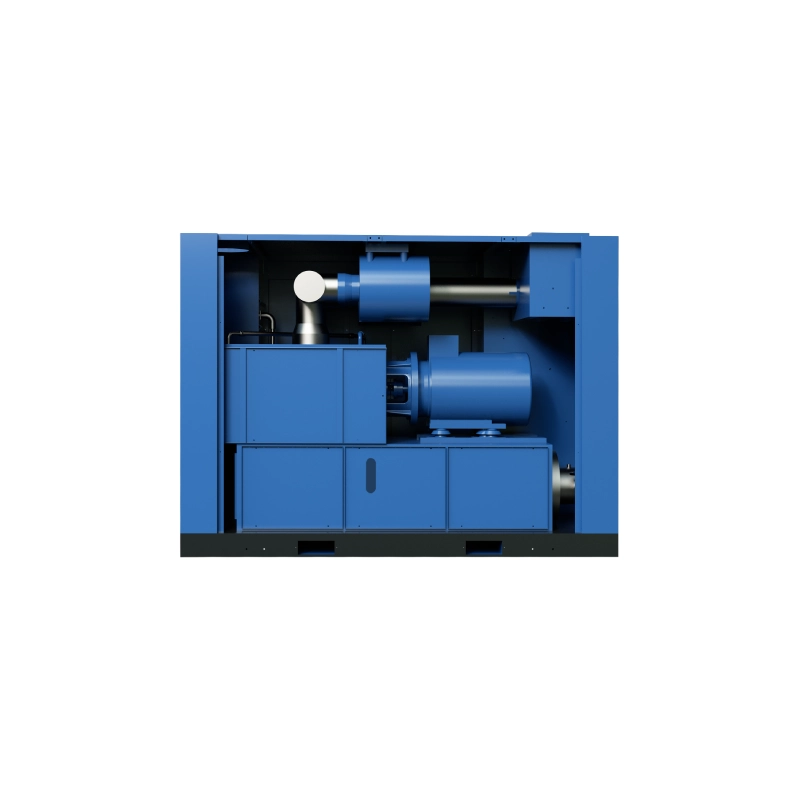

The blower features an oil-free screw design that eliminates the need for lubrication, ensuring a clean and uncontaminated compressed air supply. This makes it suitable for applications where oil contamination is not acceptable, such as in sensitive production processes or environments that require strict air quality standards.

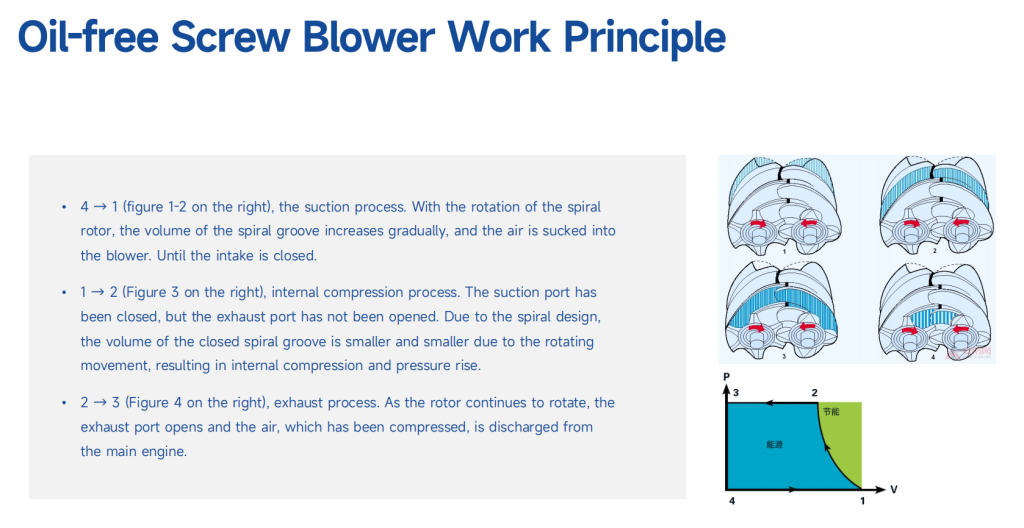

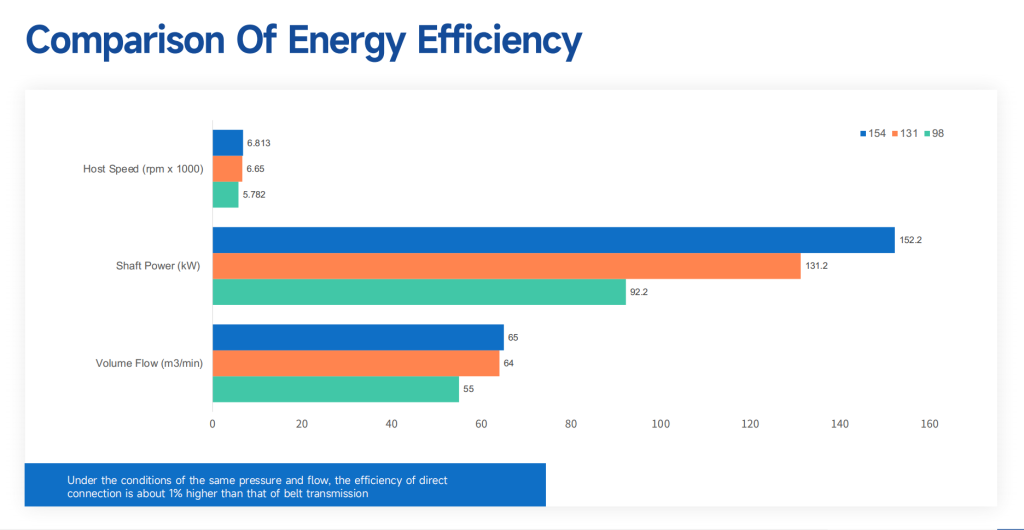

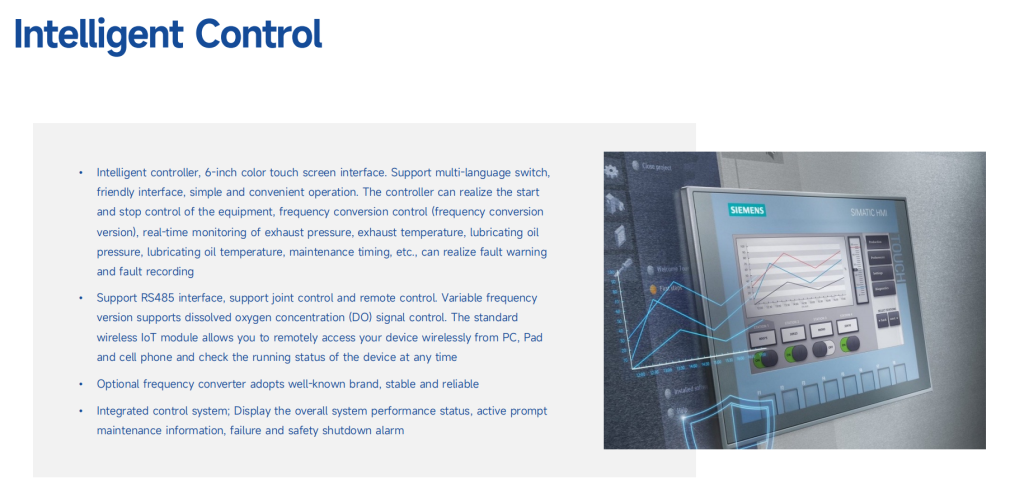

The oil-free screw technology efficiently compresses air while minimizing energy loss. This results in energy savings and reduced operating costs. The blower is equipped with an advanced control system that optimizes performance and energy efficiency, maintaining stable air pressure and providing a consistent flow of oil-free compressed air.

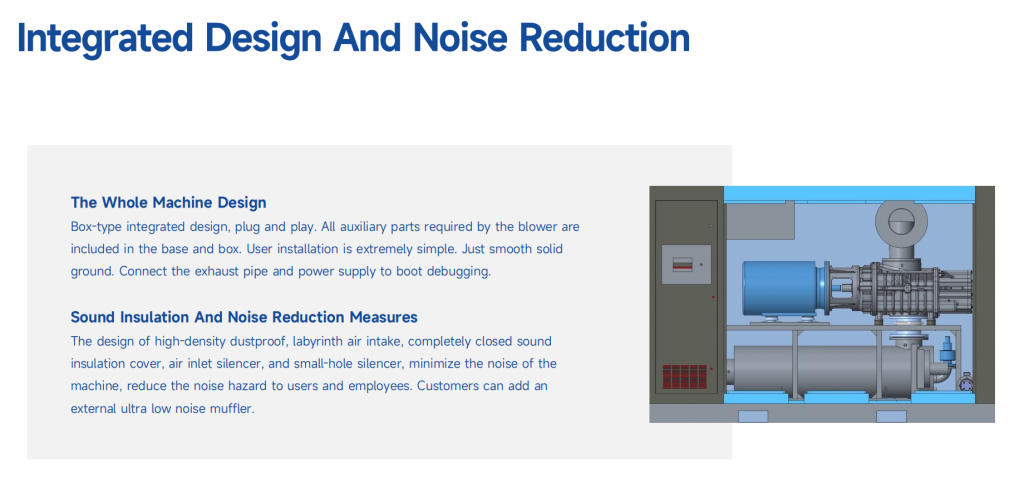

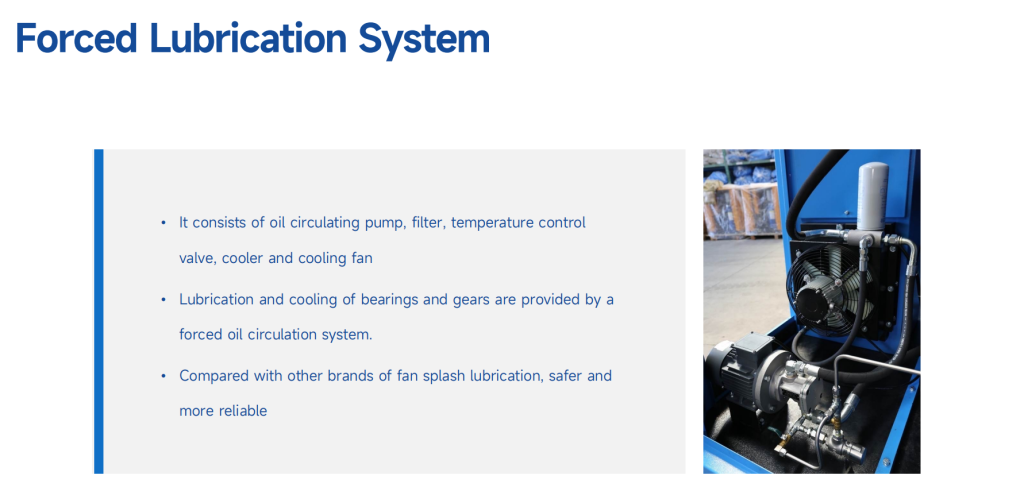

The blower is built with high-quality materials and components that ensure durability and reliability. Its robust construction and advanced cooling system enhance its lifespan, making it suitable for continuous operation even in demanding industrial environments.

Additionally, the blower is designed for easy operation and maintenance. Its user-friendly control system simplifies the operation process, and routine maintenance tasks are optimized to minimize downtime and maximize productivity.

Overall, the Oil-free Screw Air Blower is an excellent choice for industries that require clean and oil-free compressed air. Its advanced technology, energy efficiency, and reliability make it a preferred product for ensuring high-quality air supply and meeting stringent air quality standards.

Especificaciones del producto

Especificaciones del producto