Details

UD-VPM - Luftansaugsystem

Dem Chassis wurden Vorfilterschwämme, Staubfilter und Baumwolle hinzugefügt, um die Belastung der Luftfilterung zu verringern und die Lebensdauer der Luftfilterung zu verlängern. Reduzieren Sie die Verstopfung des Kühlers, um die effiziente Wärmeableitungsleistung des Kühlers sicherzustellen.

Nanofiltermaterial, Filtrationspräzision F8, Filtrationseffizienz 99,99%, um eine saubere Luftzufuhr zu gewährleisten, die Belastung durch Ölkernabscheidung, Ölfilter und Schmieröl zu verringern und die Lebensdauer zu verlängern. Und um den Saugdruckunterschied effektiv zu reduzieren, die Saugbelastung zu verringern und eine stabile Leistung zu gewährleisten.

Einlassventil mit großem Durchmesser, einfach, bequem, reaktionsschnell, geringer Druckabfall.

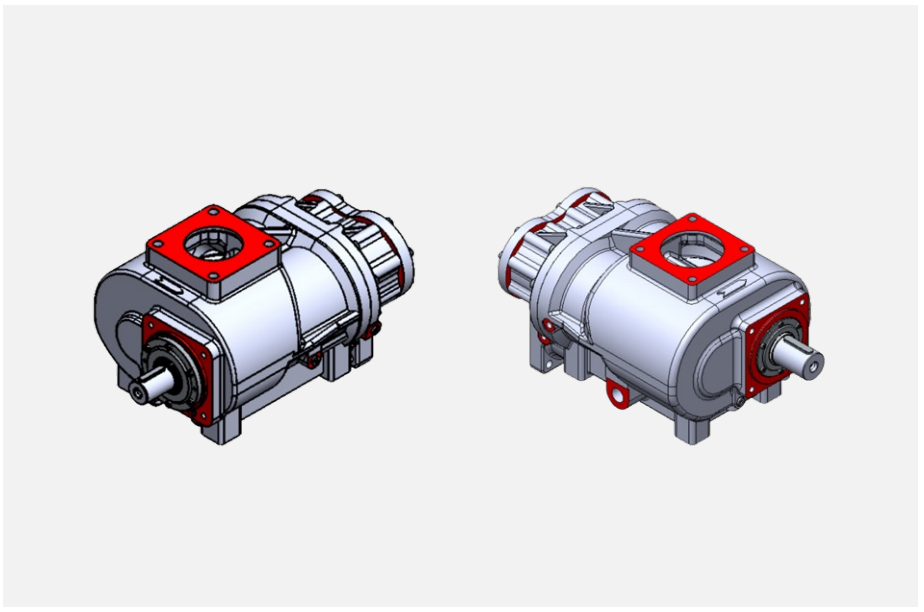

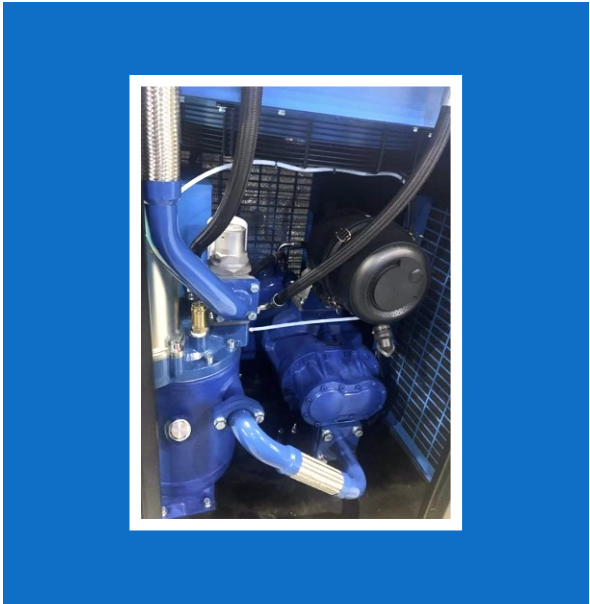

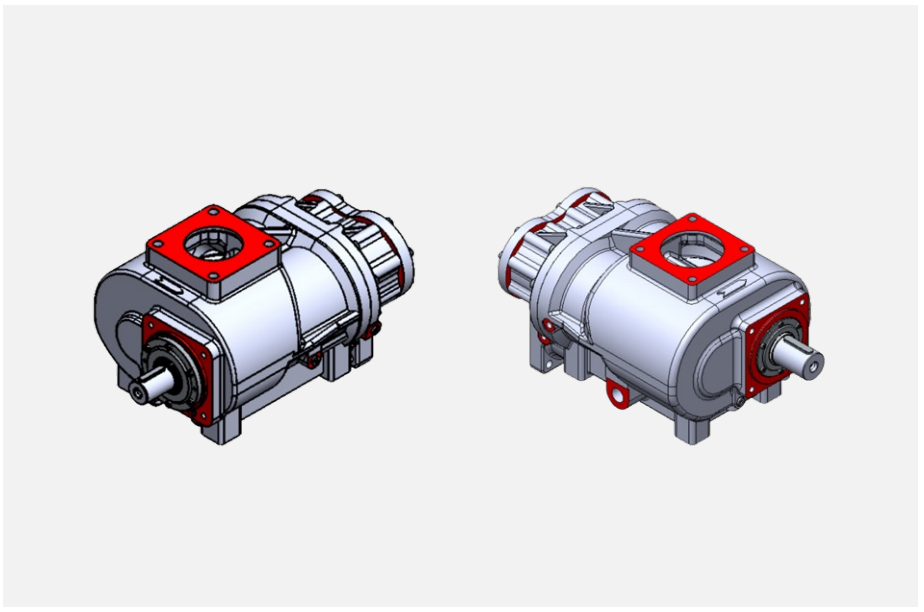

UD-VPM - Verdichterstufensystem 1

Effizientes Verdichterende:

Durch den Einsatz einer neuen Leitungsgeneration werden Dichtungen und Flüssigkeitsverluste besser optimiert und eine hervorragende Leistung erzielt.

Unter Verwendung der neuesten Methode zur Bewertung von Form- und Positionstoleranzen werden die Anforderungen der Schraubmaschine umfassend berücksichtigt, es wird eine angemessene Verteilung des Spiels, eine hervorragende Leistung und eine hohe Zuverlässigkeit gewährleistet.

Berechnen Sie die Öleinspritzmenge überall genau und kühlen Sie den Kompressionsprozess vollständig, um sicherzustellen, dass die beweglichen Teile vollständig geschmiert werden können.

Individuell gestaltete Saug- und Auslassöffnungen für ein optimales Kompressionsverhältnis.

Durch die Verwendung importierter SKF-Lager ist die Lebensdauer hoch und die Kommunikation mit der Lageranwendung, Konfiguration, Schmierung, Lebensdauer usw. ist vollständig gewährleistet.

UD-VPM - Verdichterstufensystem 2

Der magnetische Stahl des ölgekühlten Permanentmagnet-Frequenzumrichtermotors besteht aus Eisen und Bor, das eine hohe intrinsische Koerzitivfeldstärke aufweist, die Anti-Entmagnetisierungsfähigkeit erhöht und die Lebensdauer verlängert.

Nimmt eine vollständig abgedichtete Struktur an, die ursprüngliche Motorgehäusestruktur, und verwendet auch ein Spiralkühlmittel Durchgang, gleichmäßige Kühlung, Vermeidung von Temperaturstaus durch Kühllücken, Es bilden sich keine lokalen Hotspots, der Öldurchgangswiderstand ist geringer.

Kein Motorlüfter, höherer Motorwirkungsgrad, doppeltes Motorgehäuse, wirksame Isolierung des Betriebs Lärm.

Kompaktere Bauweise: hohe Leistungsdichte, kleines Volumen.

Darüber hinaus handelt es sich bei dem Permanentmagnet-Frequenzumrichtermotor um einen IE5-Hocheffizienzmotor.

Kontinuierliches Arbeitssystem (S1), Motorrotor und Rotorwelle des Luftendstücks koaxial, kompakter Struktur, höhere Übertragungseffizienz, geringe Geräuschentwicklung, geringe Vibration, geringere Wartungskosten.

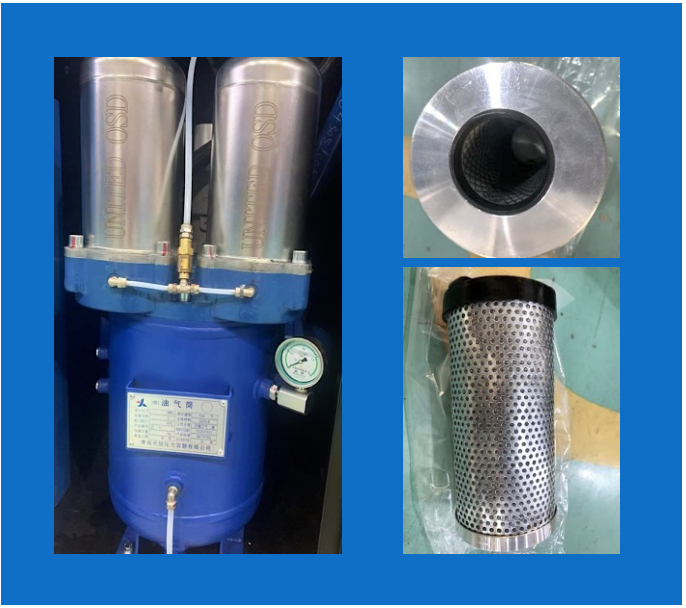

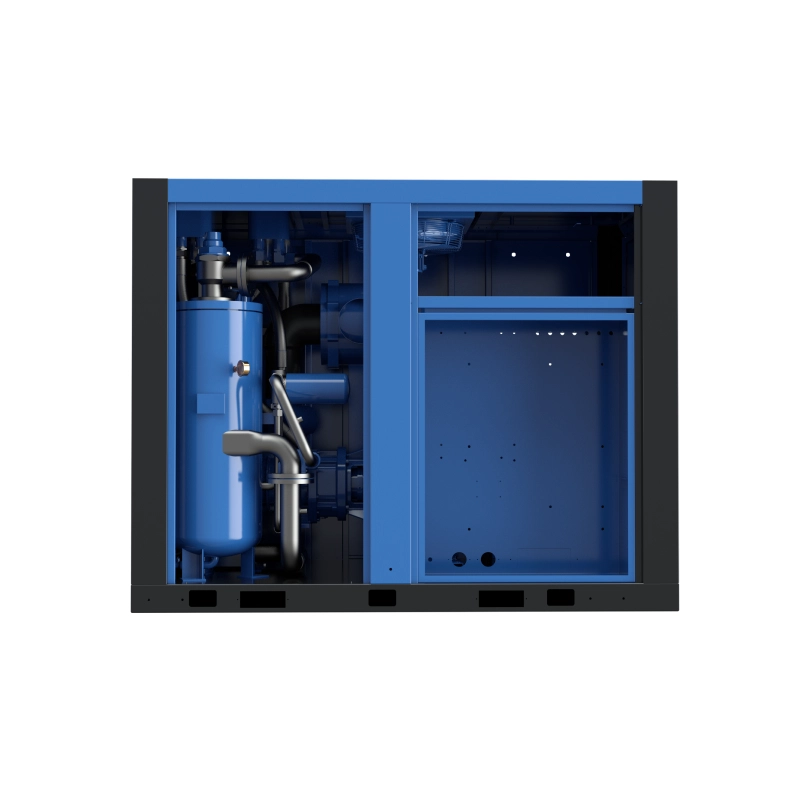

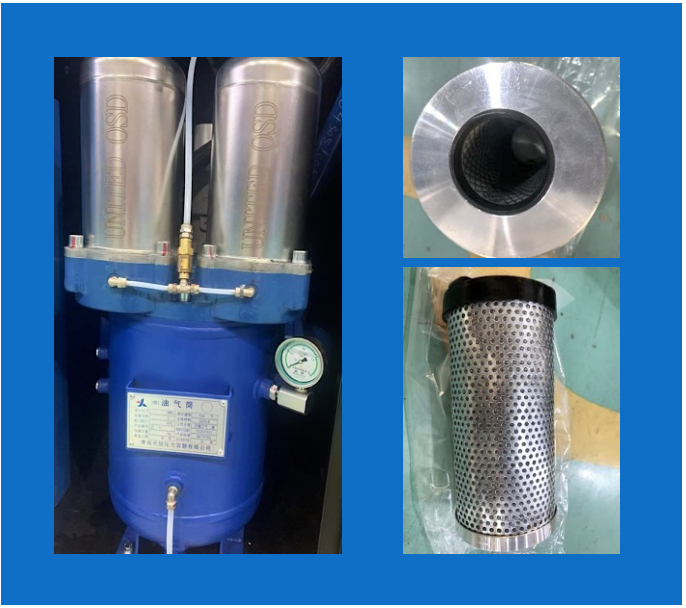

UD-VPM - Öl-/Lufttrennsystem

Spezielle Öl- und Luftzylinder-Konstruktionsstruktur:

(1) Verwenden Sie einen oberen Lufteinlass, um Lärm zu reduzieren.

(2) Verwendung eines speziell entwickelten externen Ölkerns, einfache Wartung;

(3) Durch die spezielle Konstruktion des inneren Zylinders wird der anfängliche Öl- und Lufttrennungshub erhöht, die Vortrennung von Öl und Luft ist vollständig, die Belastung des Ölkerns wird verringert, die Lebensdauer des Ölkerns wird verlängert, der Druckverlust des Ölkerns wird verringert, wodurch der Energieverbrauch gesenkt wird.

Integriertes Öl- und Luftzylinder-Enddeckeldesign, einschließlich Temperaturregelventil und Mindestdruckventil, wodurch die Gesamtstruktur kompakter wird.

Der original importierte Öl- und Luftabscheiderkern, die Falt- und Flachwicklungsstruktur, vergrößert die Filterfläche, bietet eine gute Trennwirkung, einen geringen Druckabfall, eine hohe Ölsammeleffizienz, eine gute Ölrückführungswirkung und gemäß den Wartungsbestimmungen eine Lebensdauer von bis zu 4000 Stunden.

UD-VPM - Spezialkühlmittel

Das Spezialkühlmittel für UCS-Luftkompressoren wird für den Dauerbedarf spezieller Branchen ausgewählt.

Gemäß den Wartungsanforderungen des Unternehmens beträgt die Austauschzeit bis zu 8000 Stunden, wodurch die Wartungskosten gesenkt werden.

Da der Exportölgehalt gering ist, können 4000 Stunden ohne Nachtanken garantiert werden.

UD-VPM – Einstellbare Ventilplatte

Der Öffnungsdruck der Ventilplatte kann beliebig eingestellt werden, der Kunde kann ihn entsprechend der Gassituation anpassen, den Systemdruckabfall reduzieren und mehr Energie sparen.

Großer Durchmesser, reduziert Luftstromverlust und Druckverlust.

Sensibles Handeln, verkürzt die Zeit bis zum Aufbau des Innendrucks.

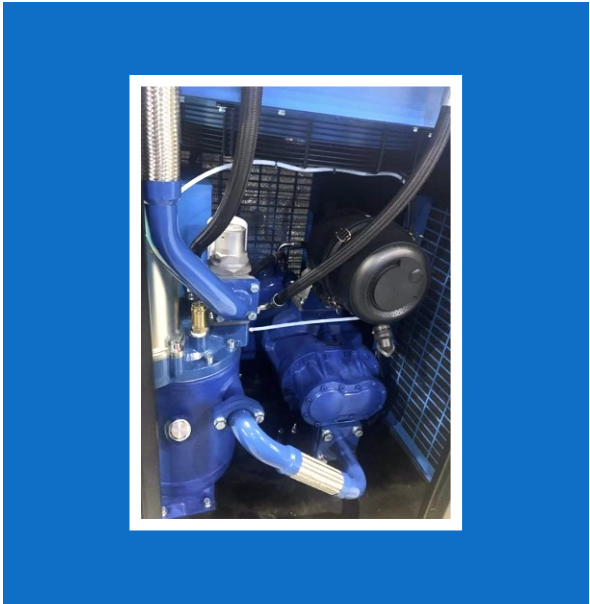

UD-VPM - Rohrleitungssystem

Alle Rohrleitungssysteme sind mit vergrößertem Rohrdurchmesser ausgelegt und verfügen über große Rohrdurchmesser, um Druckverlust und Energieverbrauch zu reduzieren.

Verwenden Sie einen Standardschlauch mit 24°-Konusdichtung, hoher Dichtungszuverlässigkeit, starker Austauschbarkeit und bequemer Demontage und Montage.

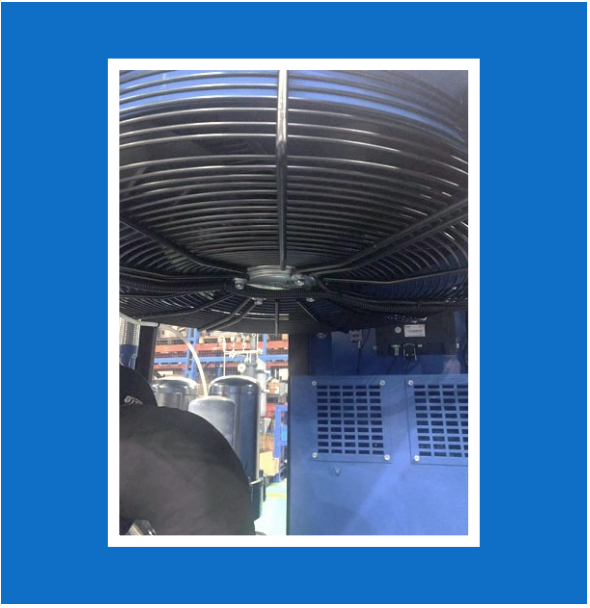

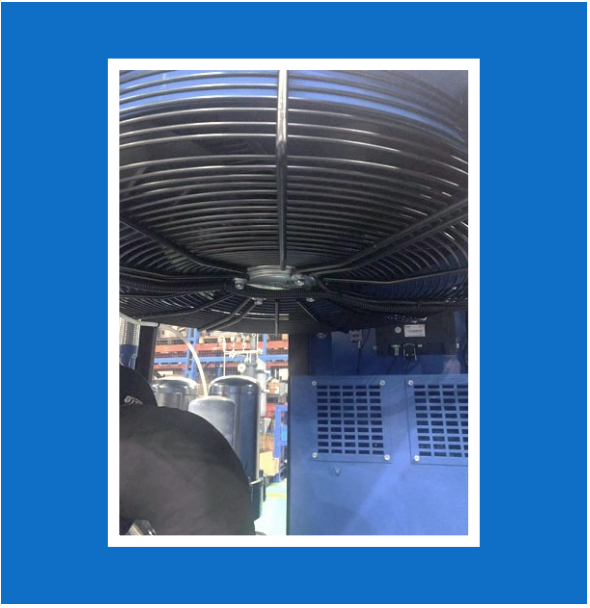

UD-VPM - Kühlsystem

Temperaturregelventil, stabile Abgastemperatur, geeignet für eine Vielzahl komplexer Umgebungen.

Der Kühler verfügt über einen Lamellenwärmetauscher mit großer Wärmeaustauschfläche, schnellem Wärmeaustausch und hoher Kühleffizienz.

Das Hauptmerkmal ist ein ausreichender Konstruktionsspielraum, um den zuverlässigen Betrieb der gesamten Maschine in der Hochtemperaturumgebung im Sommer sicherzustellen.

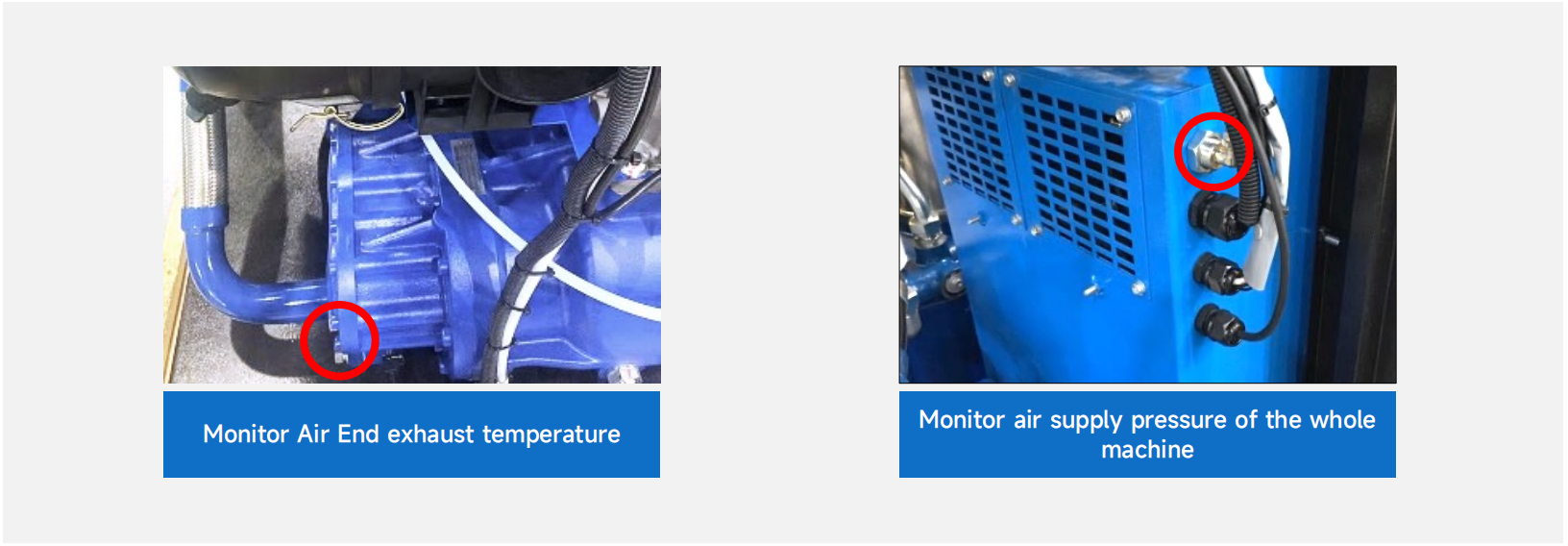

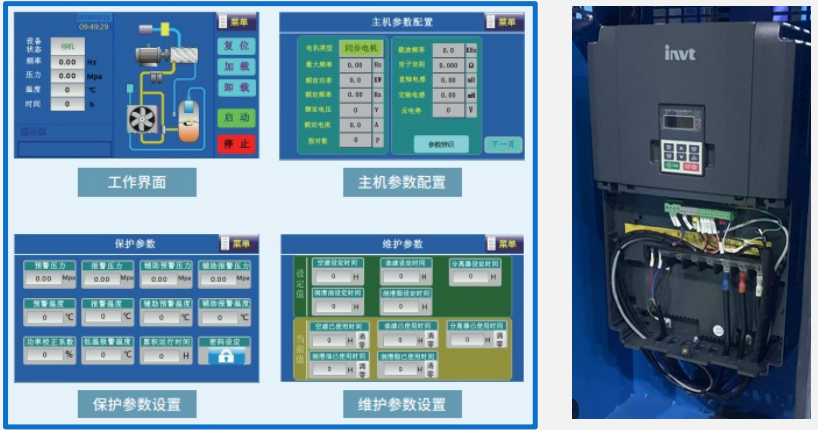

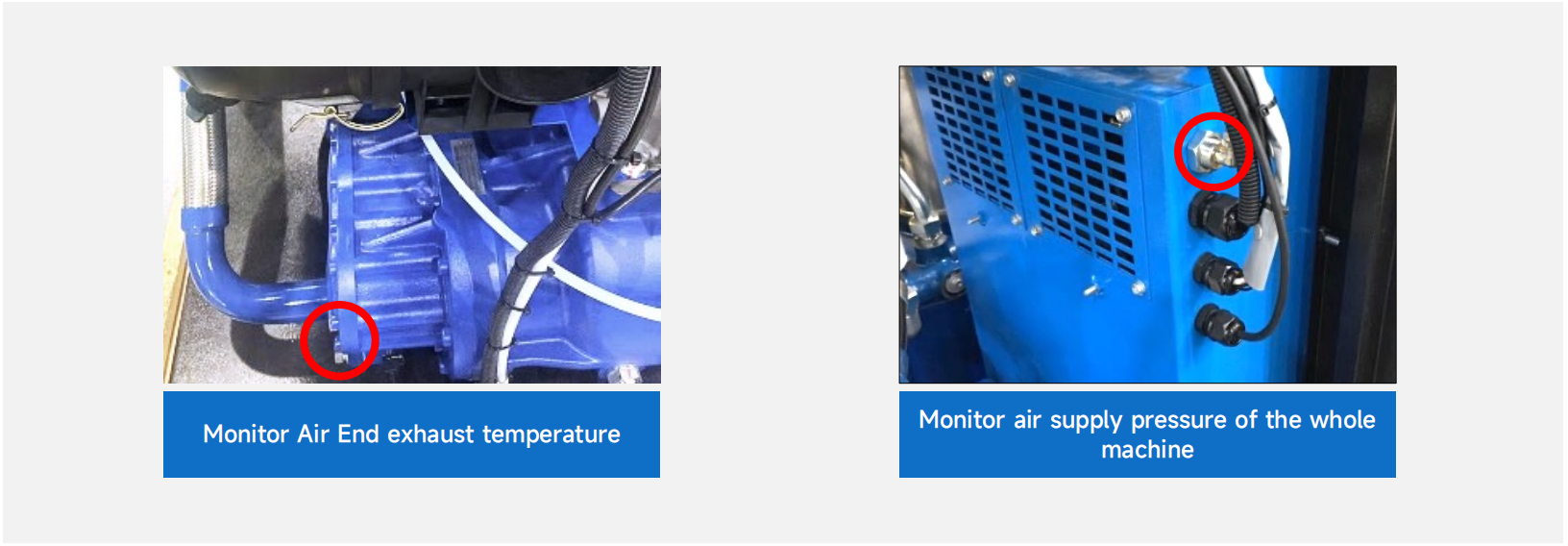

UD-VPM - Überwachungssystem

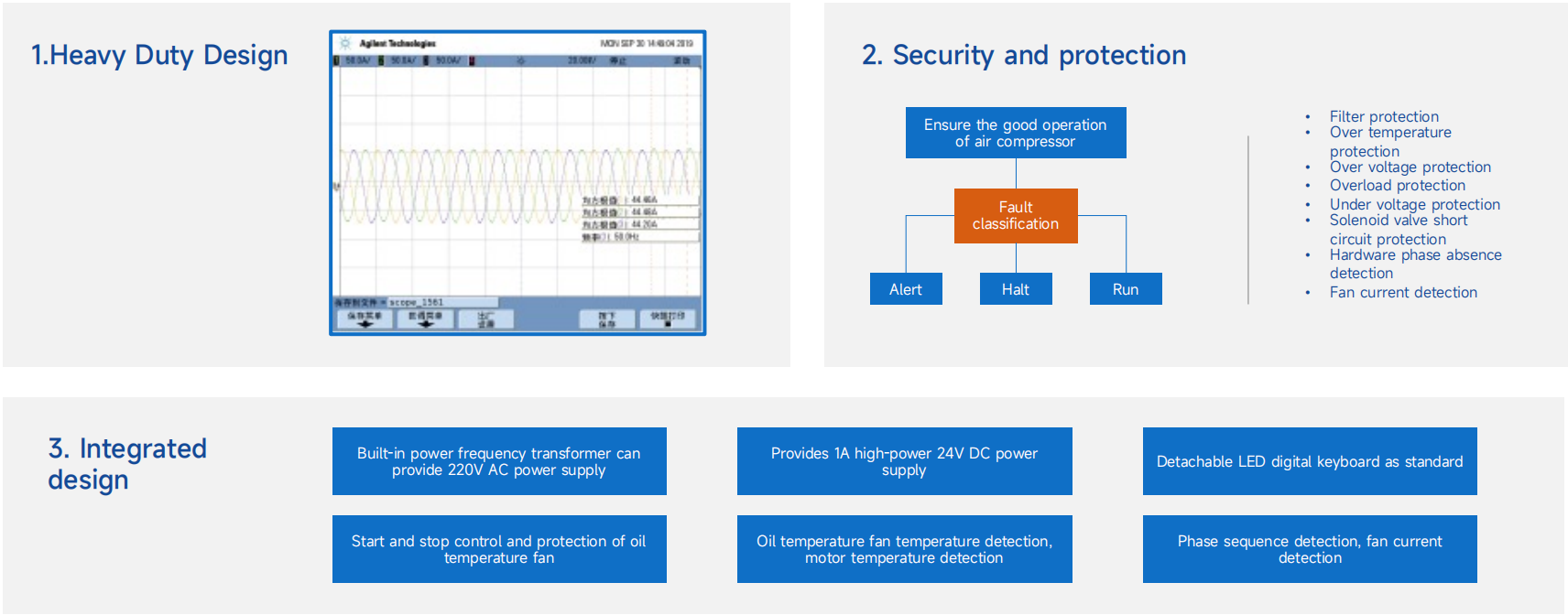

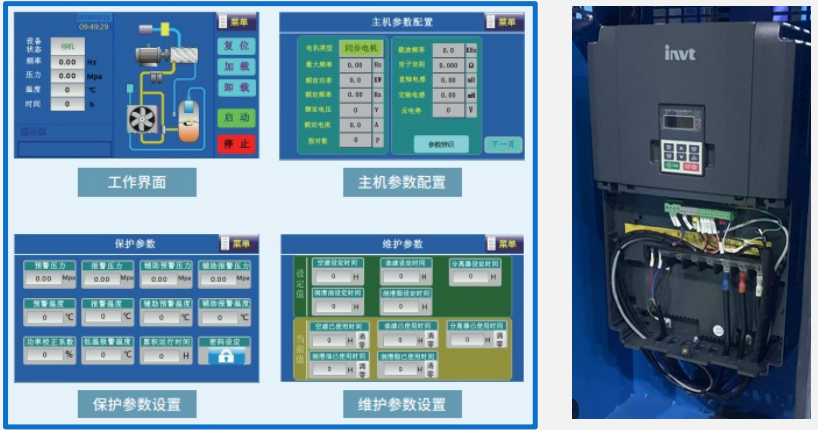

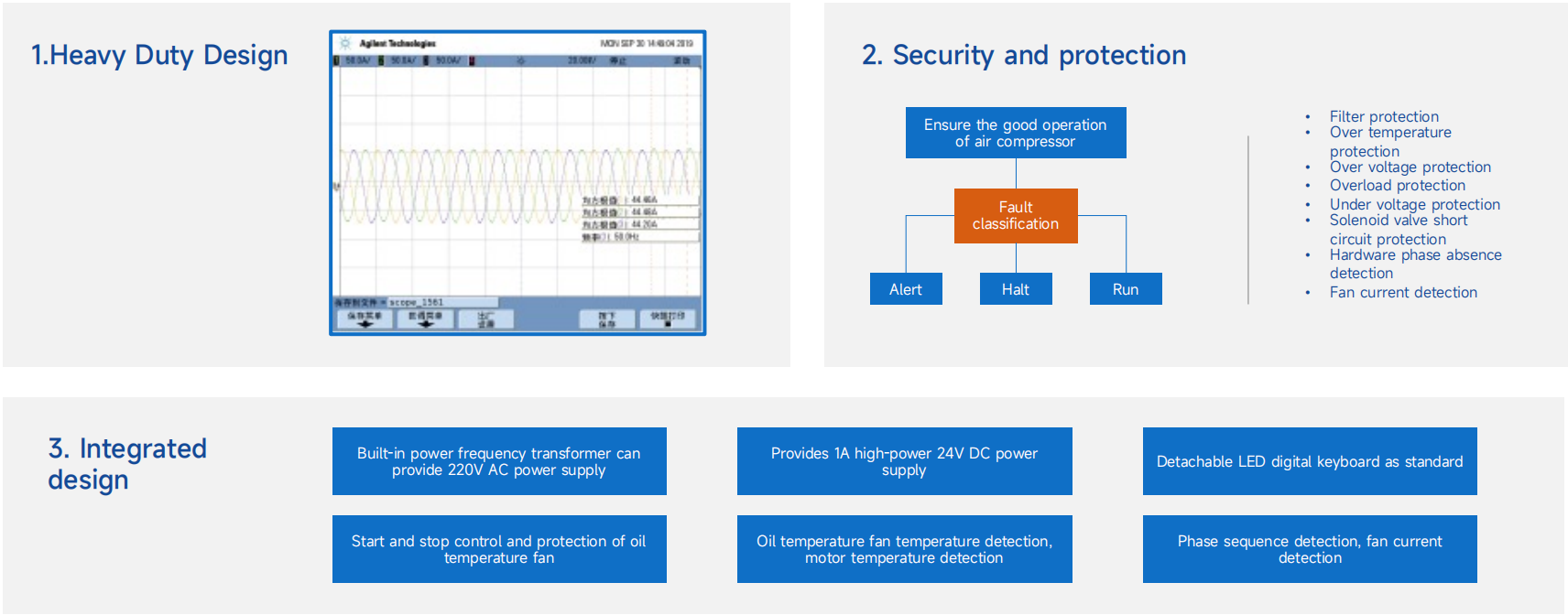

UD-VPM - Steuerungssystem 1

Das Steuerungssystem verwendet eine integrierte INVT-Wechselrichtermaschine

Starke Anpassungsfähigkeit an die Umgebung – Durch das unabhängige Design der Luftkanäle kann die Schutzwirkung des Frequenzumrichters effektiv verbessert, die Anpassung an alle Arten komplexer und rauer Feldumgebungen ermöglicht, die Produktzuverlässigkeit verbessert und die Lebensdauer verlängert werden.

Hochintegriertes Design, kleineres Volumen.

Spezielle Mensch-Maschine-Schnittstelle für Luftkompressoren.

UD-VPM - Steuerungssystem 2

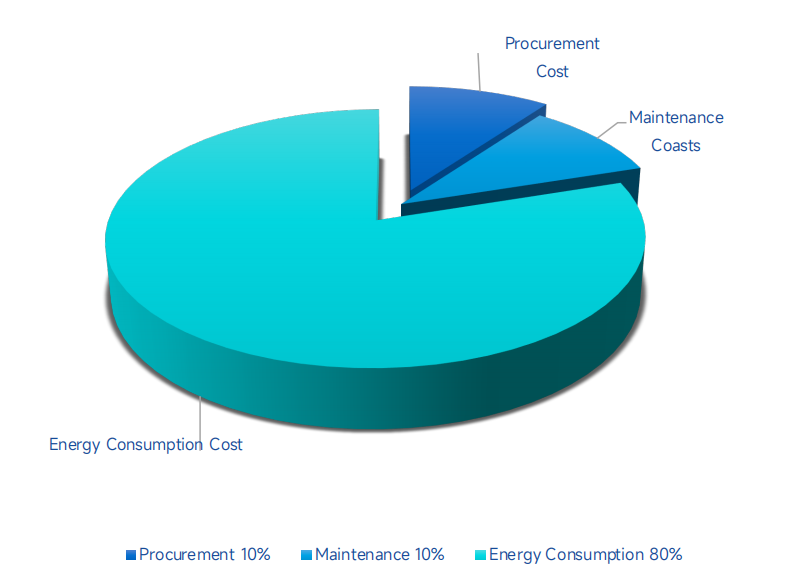

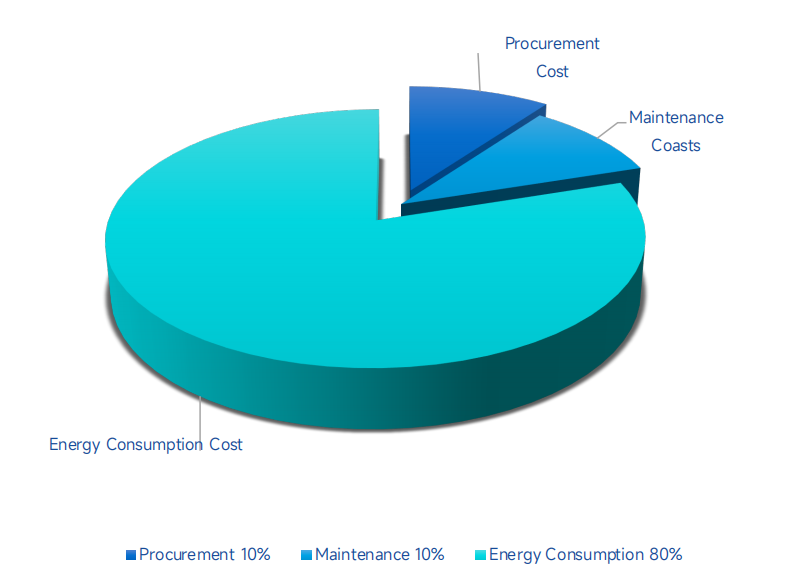

Kostenzusammensetzung des Luftkompressors

Die Kosten eines Luftkompressors setzen sich aus den Anschaffungskosten, den Wartungskosten und den Energiekosten zusammen Verbrauchskosten. Nach der Theorie der gesamten Lebenszyklusbewertung sind die Beschaffungskosten nur beträgt weniger als 101 TP3T und die Betriebskosten betragen mehr als 901 TP3T.

Daher sind die Strom- und Wartungskosten für die Kostenkontrolle des Kunden besonders wichtig.

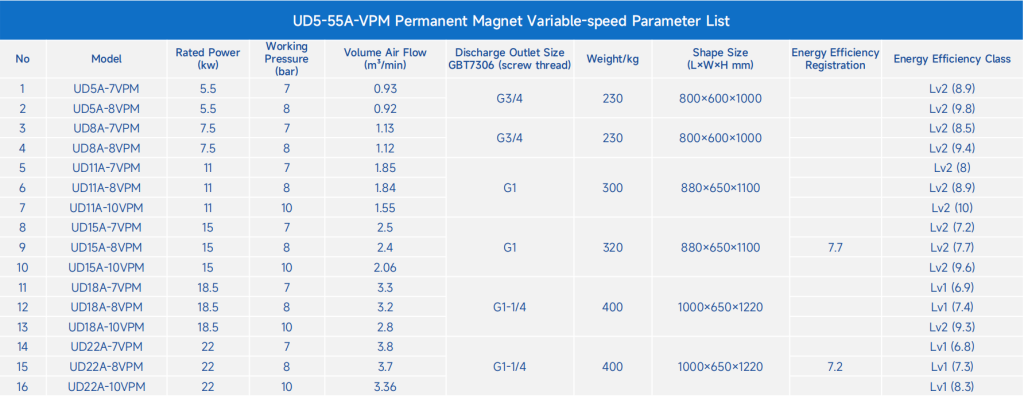

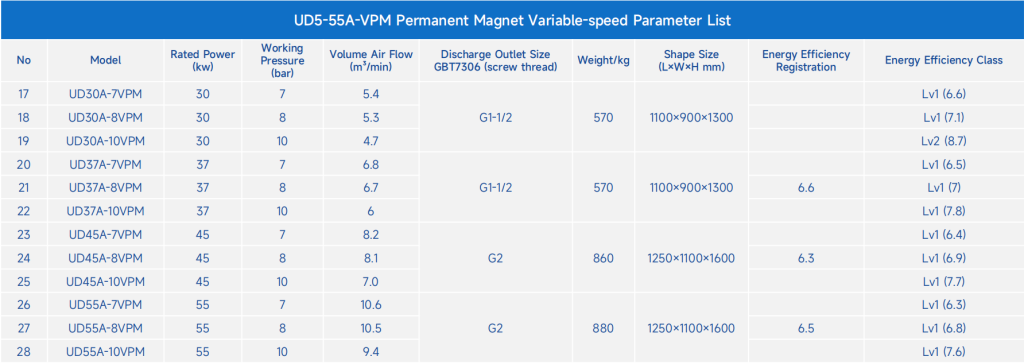

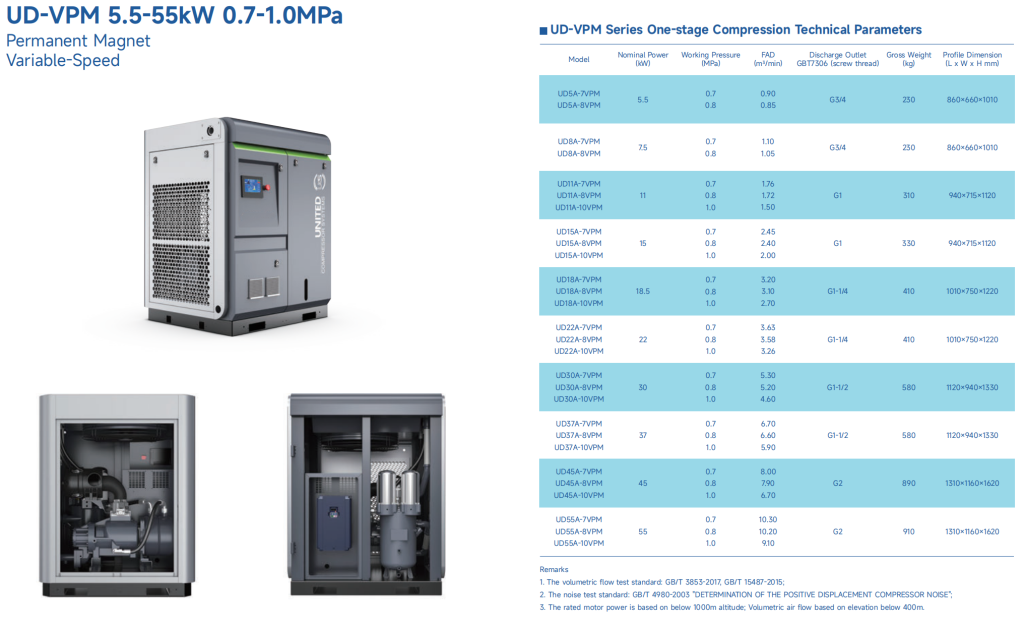

Produktspezifikationen

Produktspezifikationen