Compressed Air Cost Accounting: Essential Strategies for Cost Reduction and Efficiency

Release time: 2025-08-15

Compressed air systems are integral to industrial production, powering processes from manufacturing to automation. However, many companies overlook the full cost structure, leading to inefficiencies and higher operational expenses. Understanding compressed air cost accounting is crucial for businesses seeking to optimize energy usage and reduce overall costs.

This article breaks down the key components of compressed air costs and presents effective strategies for reducing energy consumption, maintenance costs, and improving overall efficiency.

I. Understanding the Composition of Compressed Air Costs

To accurately manage compressed air costs, businesses must first understand the various components that contribute to the overall expense. These include equipment, energy usage, maintenance, and infrastructure.

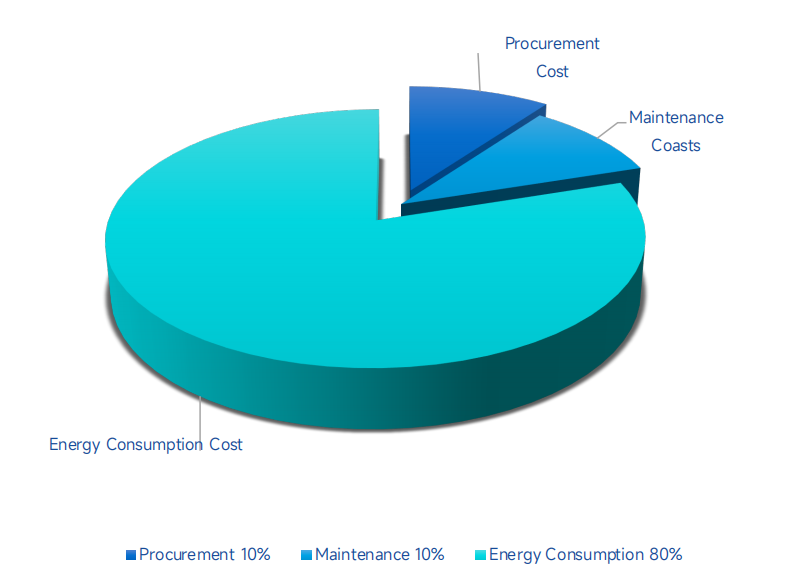

1. Equipment acquisition cost: It mainly includes the procurement costs of equipment such as air compressors, dryers, filters, and air receivers. The prices of different types, brands, and specifications of equipment vary greatly. For example, the prices of screw air compressors and piston air compressors are different. Well – known brand equipment usually has a higher price, but it may have more advantages in terms of stability and energy efficiency.

2. Energy consumption cost: This is the main part of the compressed air cost, generally accounting for 70% – 80% of the total cost. The energy cost depends on the equipment power, operating time, load/unload utilization rate, and unit energy consumption cost.

For example, an air compressor with a power of 55kW, if it runs for 10 hours a day, and the electricity price is 0.8 yuan per kilowatt – hour, calculated based on 22 working days in a month, the monthly electricity cost is 7656 yuan.

3. Maintenance cost: It includes the daily maintenance, regular maintenance, replacement of vulnerable parts, and possible repair costs of the equipment. For example, the air filters, oil filters, and lubricating oil of the air compressor need to be replaced regularly, usually every 2000 – 4000 hours of operation, and the cost of each replacement varies from several thousand yuan. Equipment failure repair may also bring additional costs and production downtime losses.

4. Installation and infrastructure cost: The installation cost includes the installation and commissioning costs of the equipment and the infrastructure construction costs. The infrastructure cost covers the cost of factory space occupation, ventilation and heat dissipation facilities, pipeline laying, etc. If the factory needs to be renovated to meet the equipment operation requirements, this part of the cost should not be underestimated.

II. How to Estimate Compressed Air Costs

Accurate compressed air cost estimation requires analyzing all aspects of the system, including energy use, equipment purchase, and maintenance. Here’s how businesses can estimate the overall costs:

1. Equipment purchase cost estimation: Through market research, obtain quotations for similar equipment from different suppliers. Consider factors such as equipment performance, quality, and after-sales service, and select equipment with appropriate cost-effectiveness for cost estimation. At the same time, consider the service life of the equipment. Generally, the service life of an air compressor is 10 – 15 years, and the purchase cost is allocated accordingly.

2. Energy consumption cost calculation:

Energy Cost = Equipment Power (kW) × Operating Hours (h) × Unit Energy Cost (yuan/kWh) × Load Factor

The load rate can be obtained through equipment operation monitoring. If it cannot be directly monitored, it can be estimated by referring to similar equipment or industry experience. For example, if an air compressor has a power of 75kW, an annual operating time of 4000 hours, a unit energy consumption cost of 0.75 yuan/kWh, and a load rate of 70%, then the annual energy cost = 75×4000×0.75×70% = 157500 yuan.

3. Maintenance cost prediction: Based on the maintenance manual provided by the equipment manufacturer, combined with the equipment operating time and working conditions, predict the number of maintenance times and costs per year. You can also refer to the industry average level. For example, the annual maintenance cost of a small air compressor is about 5% – 8% of the equipment purchase cost, and that of a large air compressor is about 3% – 5%.

4. Installation and infrastructure cost accounting: The installation cost can be obtained by consulting a professional installation company for a quotation; the infrastructure construction and pipeline laying costs are estimated according to the actual engineering design and material prices; the cost of factory space occupation can be calculated according to the unit area rent or depreciation of the factory building.

III. Strategies to Reduce Compressed Air Costs

1. Equipment selection optimization: Select energy-efficient equipment according to actual gas demand. For example, using a variable-frequency air compressor can automatically adjust the motor speed according to the gas consumption, reducing energy consumption.

2. Reduce energy consumption: Regularly inspect and maintain equipment to ensure good operating conditions and reduce energy consumption; promptly repair pipeline leaks to reduce compressed air waste; optimize the production process, reasonably arrange the operating time of gas-using equipment, and avoid unnecessary energy consumption.

3. Reasonable maintenance: Develop a scientific maintenance plan, regularly replace vulnerable parts, ensure the normal operation of equipment, extend its service life, and reduce maintenance costs.

4. Intelligent monitoring and management: Install an intelligent monitoring system to monitor parameters such as equipment operating status, gas consumption, and energy consumption in real time, and optimize equipment operation through data analysis to reduce costs.

The Role of Compressed Air Cost Accounting in Industrial Efficiency

In conclusion, compressed air cost accounting is essential for businesses aiming to optimize their operations, reduce costs, and improve energy efficiency. By understanding the components of compressed air costs—equipment acquisition, energy consumption, maintenance, and infrastructure—companies can pinpoint areas for improvement.

Adopting energy-efficient technologies, practicing preventive maintenance, and utilizing intelligent monitoring systems can significantly reduce both energy and operational costs, helping businesses stay competitive and environmentally conscious.

Effective compressed air cost management leads to immediate cost savings and contributes to long-term operational success. By investing in energy-efficient equipment and optimizing system operations, businesses can achieve a sustainable and cost-effective compressed air solution for their production needs.