Choosing the Right Air Compressor: Piston, Screw, and Centrifugal Compressors Explained

Release time: 2025-05-26

Air compressors are essential tools in various industries, providing compressed air for a wide range of applications. Whether you’re working in a small workshop or running a large industrial plant, understanding the differences between air compressor types is crucial for making an informed decision. In this comprehensive guide, we will explore three main types of air compressors: piston compressors, screw compressors, and centrifugal compressors, highlighting their benefits, applications, and the best industries to use them in.

Table of Contents

1. Piston Compressors: Affordable and Reliable for Small-Scale Use

Piston compressors are the most common type of air compressor and operate with a simple mechanism. These compressors use a piston inside a cylinder to compress air, which is then stored in a tank. Ideal for low-pressure applications, piston compressors are widely used in small businesses, home workshops, and DIY projects.

Advantages of Piston Compressors:

- Affordable and Easy to Maintain: Piston compressors are budget-friendly and simple to maintain, making them ideal for small-scale operations.

- Compact and Portable: Due to their small size, they are easy to move around and fit into tight spaces, such as home workshops or garages.

- Versatile Applications: Perfect for tasks such as inflating tires, powering small air tools, or operating an airbrush.

Best Applications for Piston Compressors:

- Small Workshops: Piston compressors are great for small tasks like inflating tires, spraying paint, or powering basic pneumatic tools.

- Automotive Repair Shops: Piston compressors are commonly used in smaller auto repair shops where there is a need for compressed air intermittently.

- DIY Projects: Ideal for occasional use, whether you’re using air tools or inflating sports equipment.

While piston compressors are great for lighter, infrequent tasks, they are not suitable for industries that require continuous, high-pressure air.

2. Screw Compressors: High Efficiency for Medium to Large Businesses

Screw compressors are designed for higher efficiency and continuous operation. Unlike piston compressors, energy-efficient screw compressors use two interlocking rotors to compress air, offering a more consistent airflow. These compressors are ideal for medium to large businesses where compressed air is needed continuously.

Advantages of Screw Compressors:

- Continuous Operation: Designed to work 24/7, screw compressors are ideal for industries with high-demand air needs.

- Energy Efficient: Compared to piston compressors, screw compressors are more energy-efficient, helping reduce operational costs.

- Low Noise Levels: These compressors are quieter than piston compressors, making them a suitable option for noise-sensitive environments.

- Minimal Maintenance: Fewer moving parts make screw compressors more durable and require less maintenance than piston compressors.

Best Applications for Screw Compressors:

- Manufacturing Plants: Used in factories and production lines where a constant supply of compressed air is necessary for machinery and tools.

- Construction Sites: On large construction projects, screw compressors provide reliable air for pneumatic tools such as drills and hammers.

- Automotive and Paint Shops: In industries like auto repair and paint spraying, screw compressors are invaluable for continuous air supply.

Screw compressors are ideal for businesses that need efficient, continuous, and reliable compressed air systems, especially in medium-to-large-scale operations.

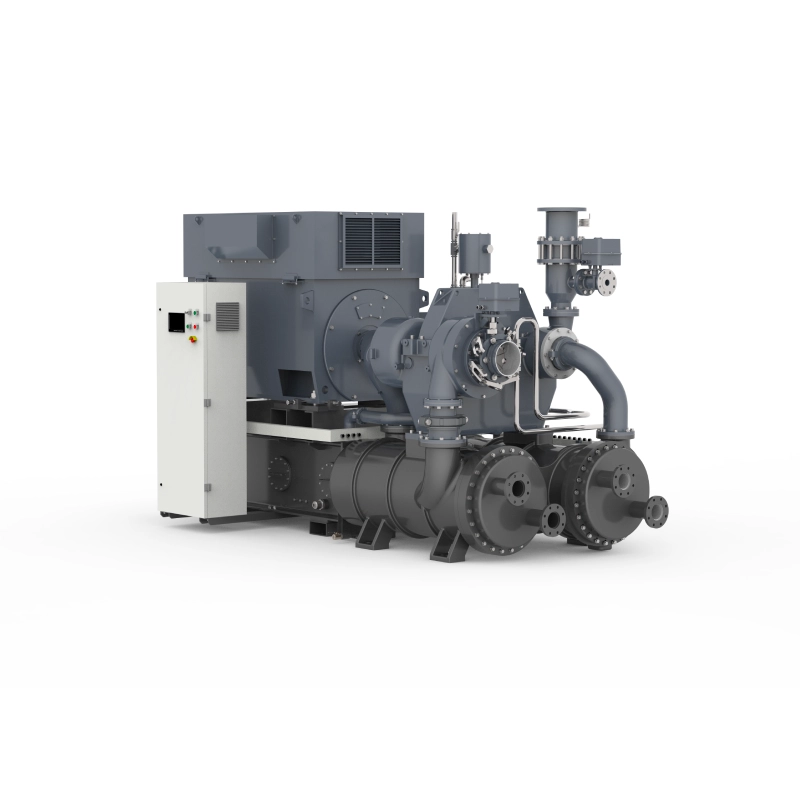

3. Centrifugal Compressors: Powerful Solutions for Large-Scale Industries

Centrifugal compressors are the most powerful and efficient compressors, designed for large-scale industrial applications. Instead of using a piston or screws, centrifugal compressors use a rotating impeller to increase air velocity, which is then converted into pressure through a diffuser.

Advantages of Centrifugal Compressors:

- High Efficiency: Centrifugal compressors offer superior compression efficiency, ideal for industries requiring large volumes of air.

- Scalability: They can easily be scaled up to meet the growing demands of large industrial plants.

- Smooth Airflow: Unlike piston compressors, centrifugal compressors provide a smooth and continuous flow of compressed air, eliminating pulsations.

Best Applications for Centrifugal Compressors:

- Petroleum and Gas Industry: Essential for gas processing, pipeline compression, and power generation in the petroleum industry.

- Chemical Plants: Used for air separation, chemical reactions, and process cooling.

- Power Plants: These compressors are commonly used for turbine cooling, combustion, and cleaning equipment in power generation.

Due to their high output and reliability, oil-free centrifugal compressors are favored by industries that require large-scale air compression solutions.

Conclusion: Which Air Compressor is Right for You?

Choosing the right air compressor depends on your specific needs and the scale of your operations. Piston compressors are the go-to option for small workshops and DIY projects due to their affordability and simplicity. Screw compressors are perfect for businesses that need continuous, reliable compressed air, offering great efficiency for medium to large operations. Centrifugal compressors, on the other hand, are designed for large-scale industries that require powerful, high-volume compressed air.

When selecting an air compressor, consider factors like energy efficiency, maintenance requirements, and the operational demands of your business. By understanding these differences, you can choose the most suitable compressor to maximize performance and reduce long-term costs.