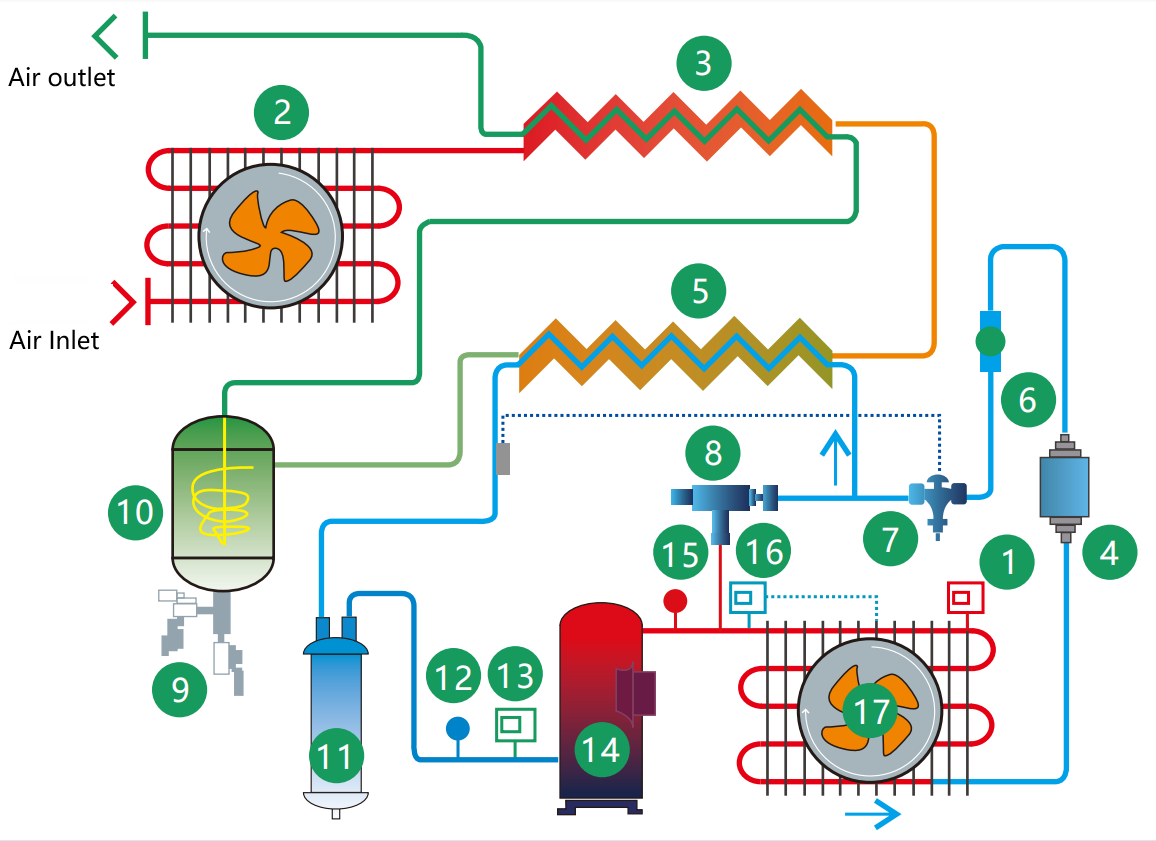

High-temperature compressed air, containing moisture and oil, enters the pre-cooler and the 'cold-hot compressed air heat exchanger.' This process pre-cools the compressed air, reducing its temperature. The cooled air then enters the evaporator of the 'compressed air-refrigerant' system, where it is cooled to a dew point temperature of 2~10℃.

During this process, moisture, oil, and some impurities are condensed. The cooled gas and the condensed moisture, oil, and impurities are separated by a gas wave separator. The moisture and oil are discharged through an automatic drain valve.

The dried compressed air is then reheated in the 'cold-hot compressed air heat exchanger,' resulting in dry compressed air that is nearly at room temperature.

Product Specifications

Product Specifications